Flange Immersion - Oil & Gas

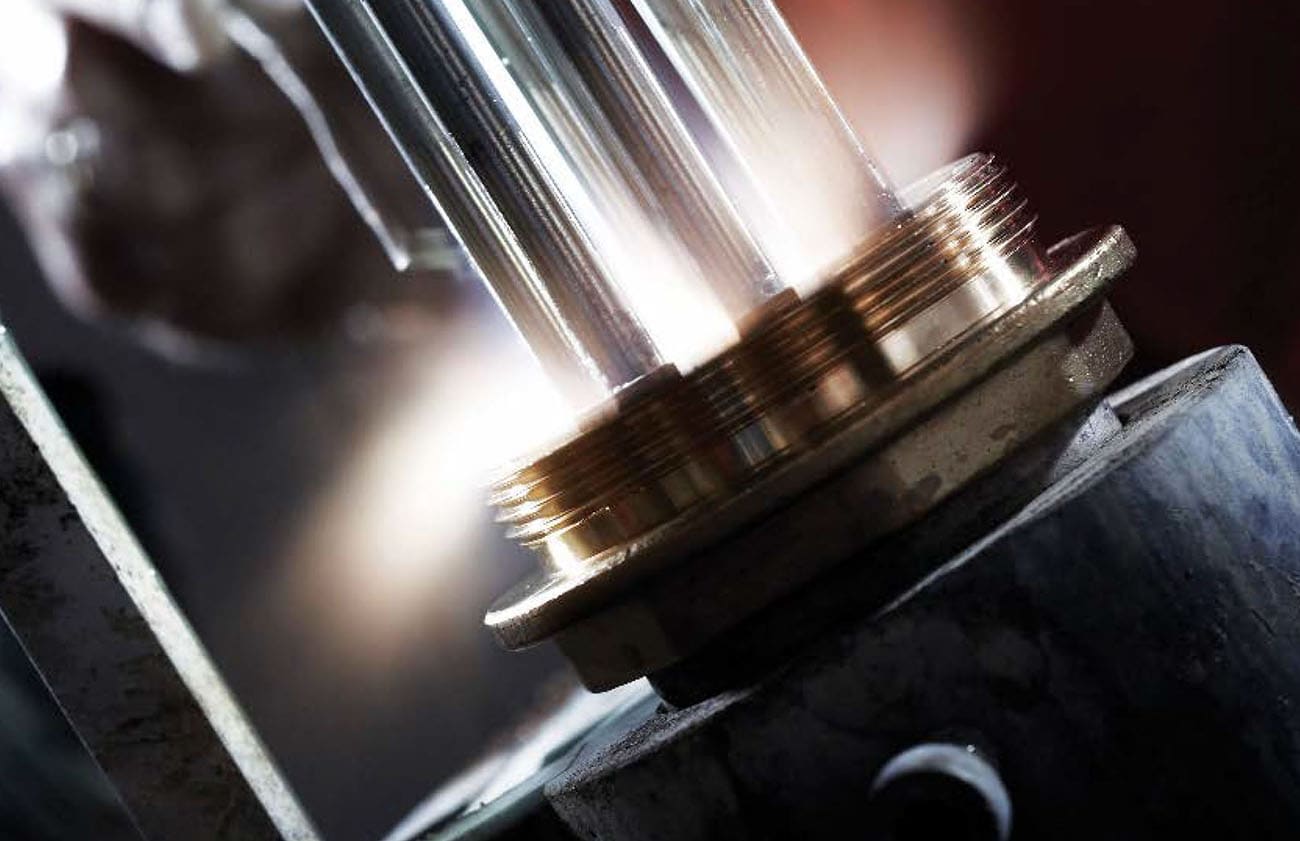

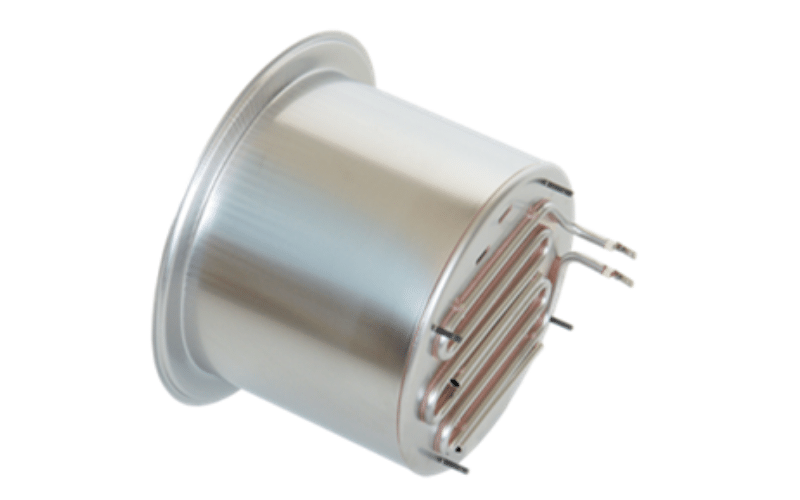

Heater type: Flange Immersion

Rating: 30kW 415V

Process: Binary Distillation

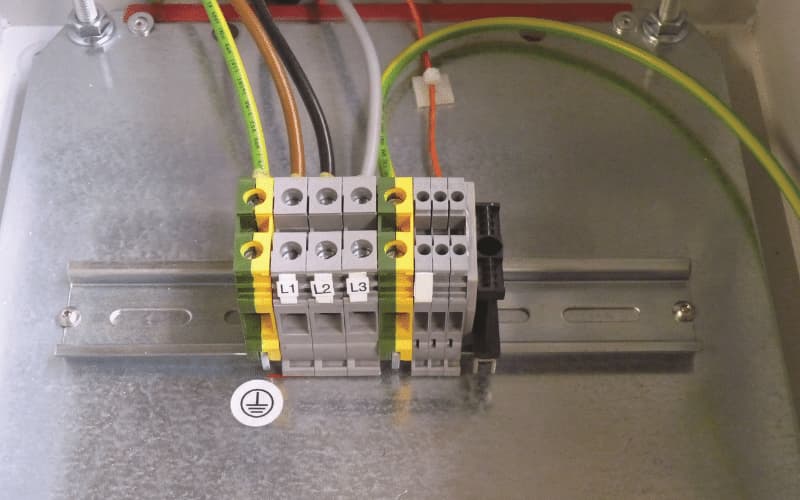

Application description: The Binary Distillation trainer was one of four training skids provided to a college in Qatar as an addition to their state of the art student training facilities. The separation of liquid mixtures and recovery of the components typically involves the distillation process. Distillation and fractionation operations are found throughout the petroleum, petrochemical and numerous other industries. This trainer separates a methanal/water mixture in a see-through, bubble cap tray column. The trainer is equipped with industry-typical process measurement and control devices. The entire trainer is controlled from an Emmersion Delta V distributed control system (DCS).

The main heat input to the distillation column is provided by a re-boiler liquid vessel at the bottom of the column. The bottom product (least volatile feed mixture component) is removed from the re-boiler at operator determined rates to achieve optimum distillation conditions. The heat input into the column is controlled to maintain desired distillate production rates and temperature distribution in the column to a maximum process temperature of 100°C.

%201_element.jpg)

%201-industrial.jpg)

%201-projects.jpg)

%20(2)%201500x500.jpg)