Heavy Industrial Immersion Heater with IoT

Heatrod manufacture a wide range of heavy industrial immersion heaters for commercial and industrial applications. With our customers facing increasing energy costs we have introduced the option to include our digital temperature controller into many of our heavy industrial immersion products.

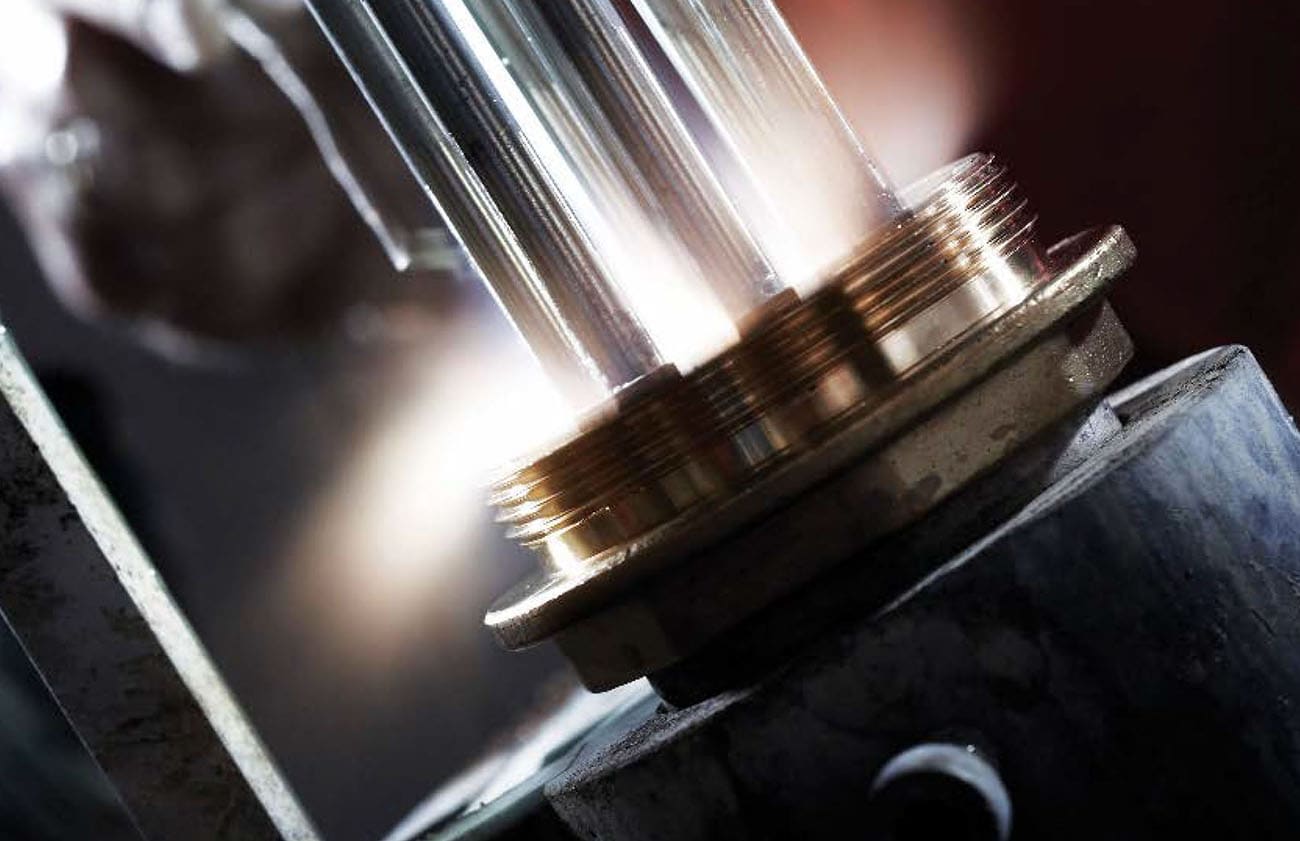

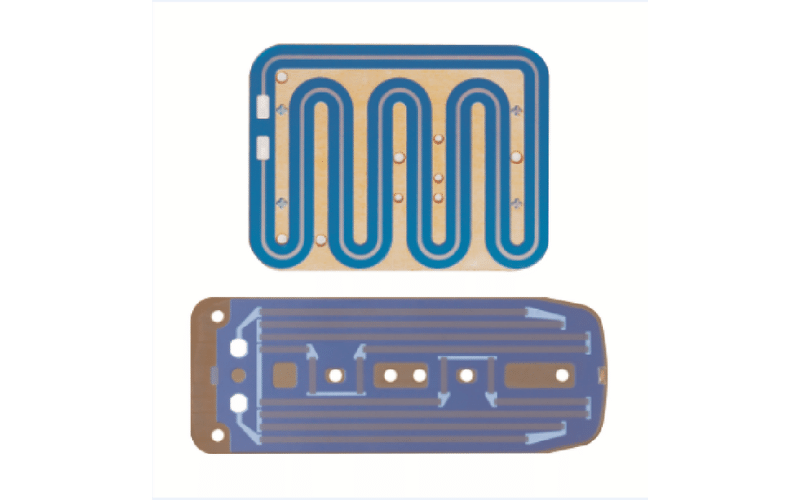

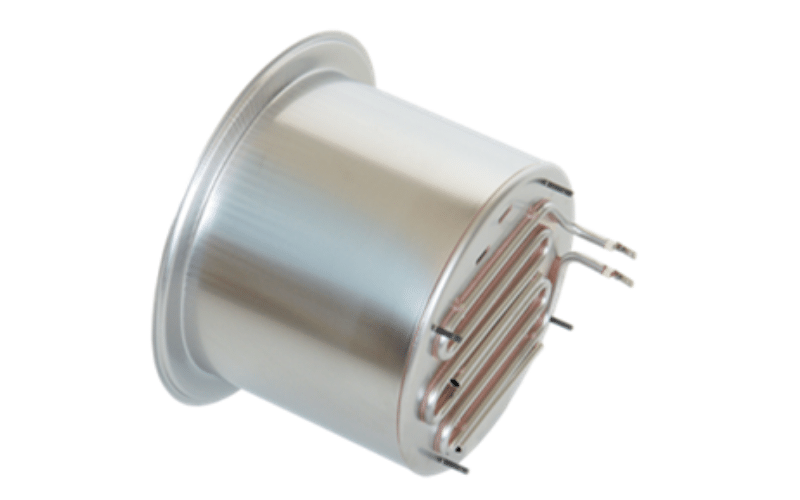

The example shown is used in de-ionised water for cleaning processes.

Example of Applications

- Commercial cylinder heating (Tanks/Vessels)

- Industrial Flow Heating (Pipes/Circuits)

- Industrial Heating Applications (Extrusion, Tool Heating, etc)

Benefits

- Improved Control/Improved Accuracy

- Reduced Energy Costs

- Increased Control Options (eg. Aux control for pump)

At a basic level this gives the accuracy of PID temperature control so limiting overun on temperatures and energy usage.

For more advanced users, our digital controllers can be connected to our secure cloud based management system allowing users the ability to carefully monitor and manage the energy usage of our heaters. Monitoring features allow full visibility of live temperatures and energy usage in your applications which, in turn, allows power optimising decisions to be made.

Usage patterns and associated energy usage can then be managed by the use of simple daily/weekly load schedules.

Heating schedules can also be linked to low cost tariffs based on scheduling and to avoid high cost times such as Triad periods which are introduced for commerical users between the months of November and February.

In advanced cases, users will be able to link their Backer IoT controllers to variable tariff information provided by energy generation companies. The controller will then optimise it's heating patterns in order to reach required temperatures whilst using the lowest cost half hourly periods.

The Backer IoT controller can be applied to all of our products either by being built into the unit, where space allows, or by incorporating into a linked control/switch panel.

-

Technical data

Flange

6 ⅝" Tri-Clover Flange

Rating

24kW, 400V Single Stage

No. of Elements

12

Temperature Controller

Backer HRDC

Finish

Electro Polish

Terminal Enclosure

IP66 Stainless Steel 304 - 240 Grit

Safety

GTLHR 0-120°C

Contactors

Siemens

Internal single stage control circuit

%201_element.jpg)

%201-industrial.jpg)

%201-projects.jpg)

%20(2)%201500x500.jpg)