Tubular & Finned Elements

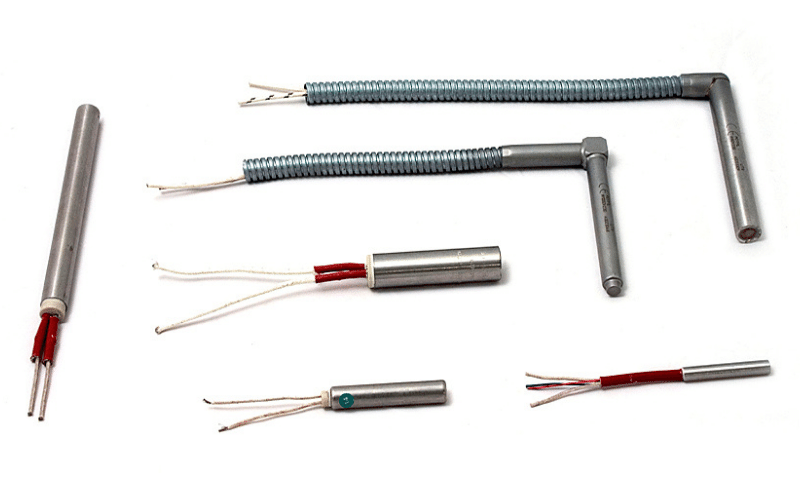

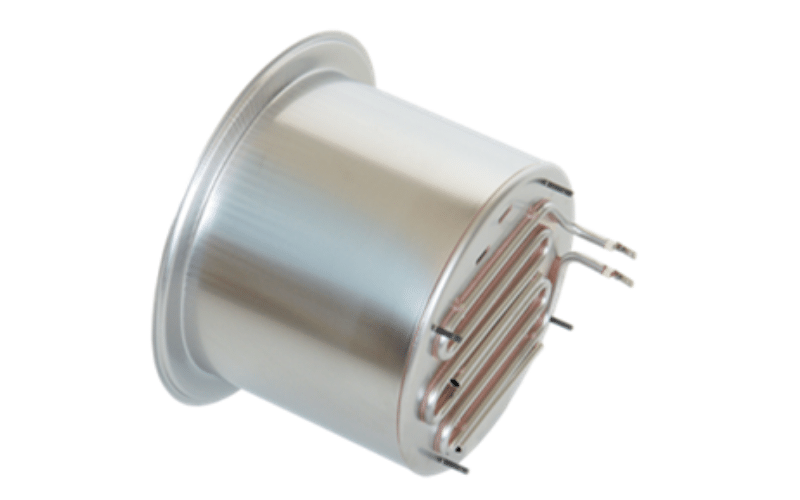

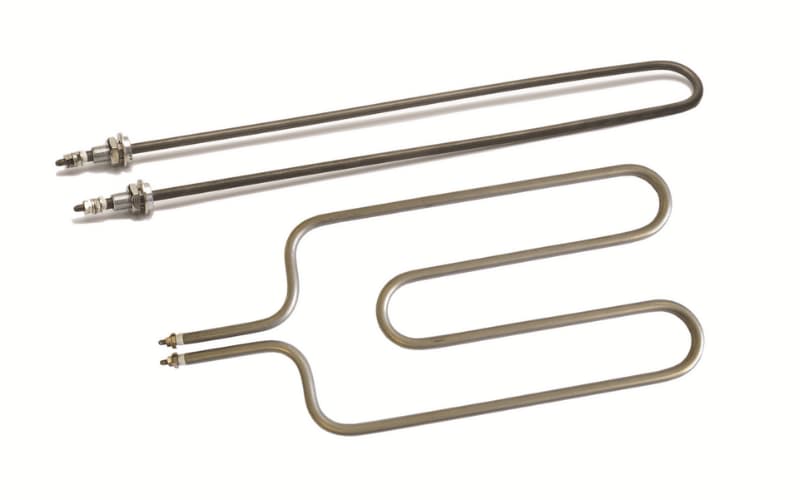

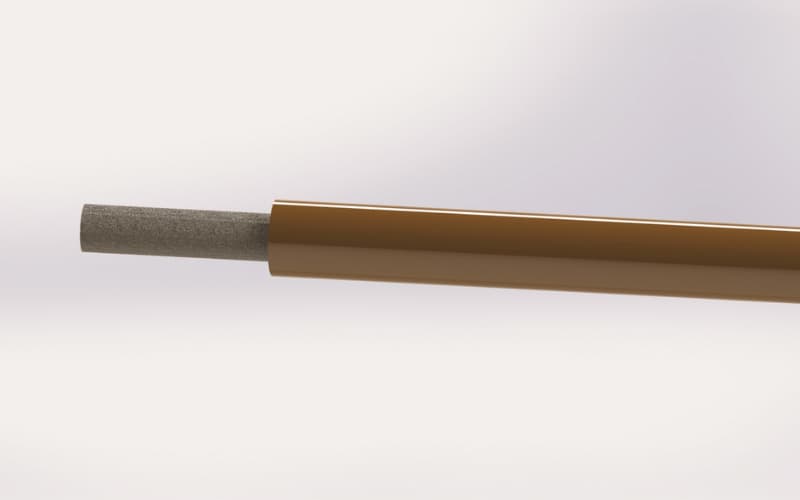

Tubular elements can be used in a range of applications; from air, water, oil to chemical solutions and defrost. They are a versatile means of heating an application and can be straight, or formed to a required shape and can reach temperatures of 800°C.

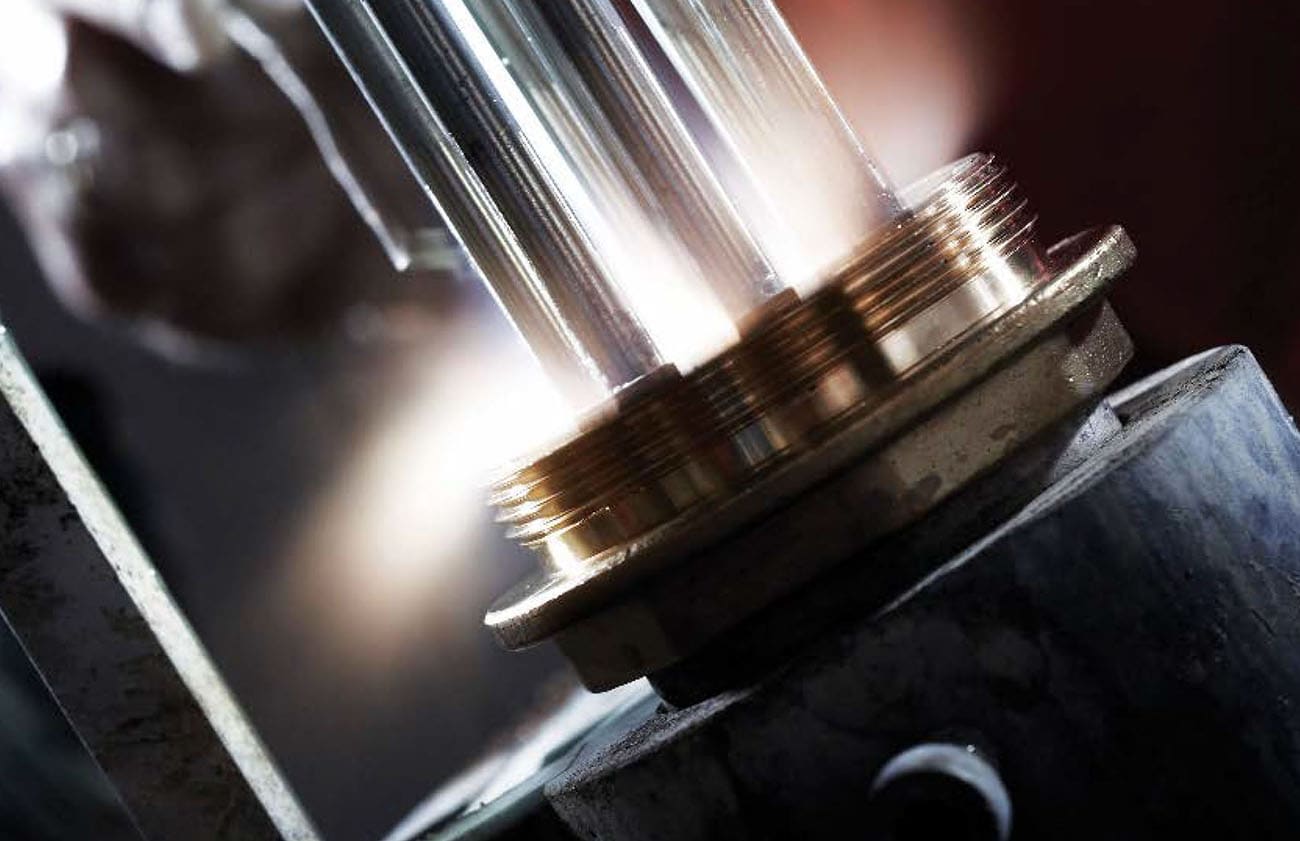

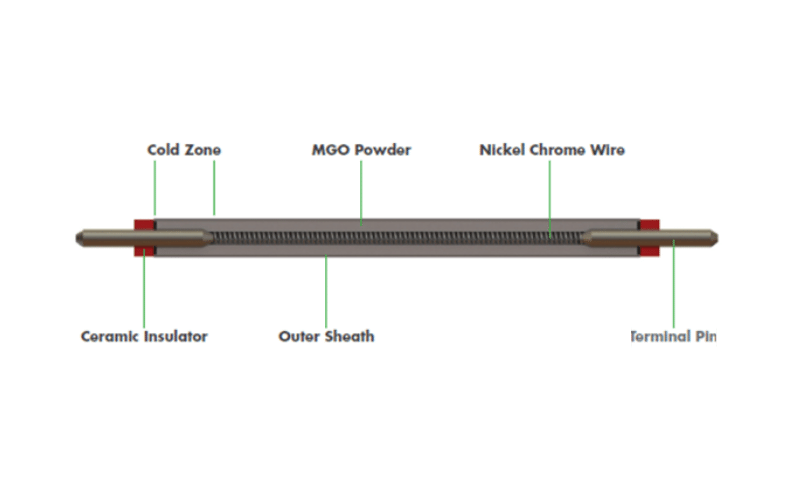

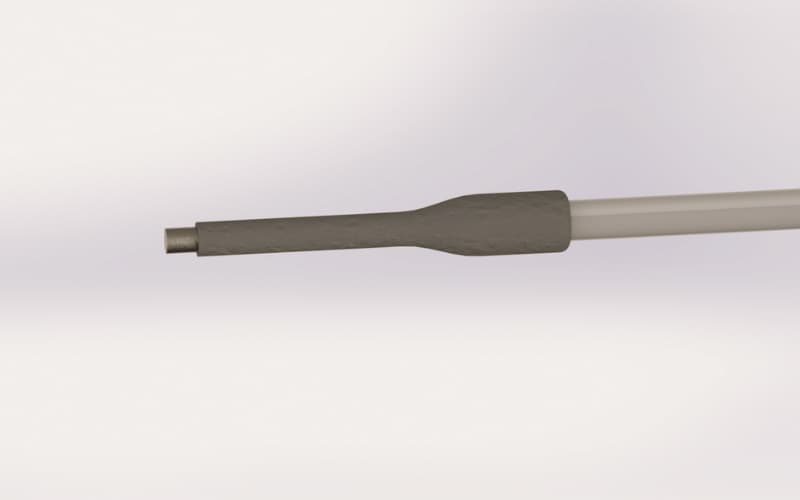

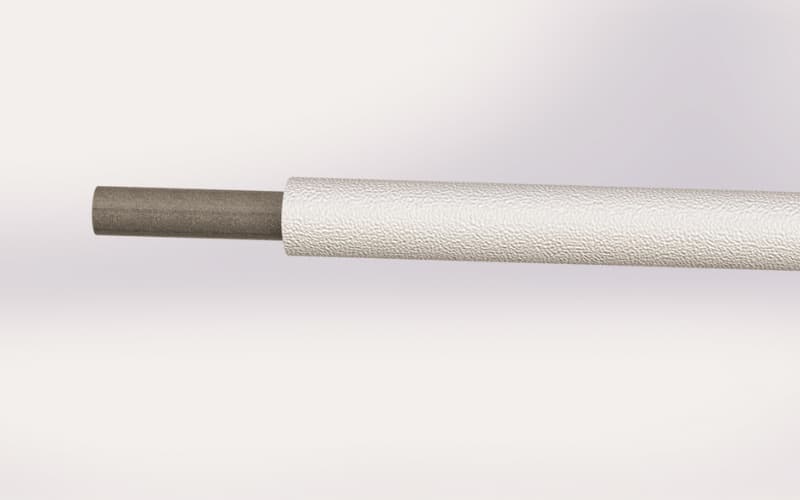

A tubular element consists of nickel chrome resistant wire, which is spot welded to a terminal pin. The nickel chrome wire is insulated by MgO powder, which is then housed in an outer sheath.

Example of Applications

- Defrost (refrigeration)

- Air/wet applications

- Oil/chemical applications

- Castings

- Food industries

Benefits

- Available as straights, or can be formed to drawings or samples

- Custom wattages and voltages available with varying cold zones

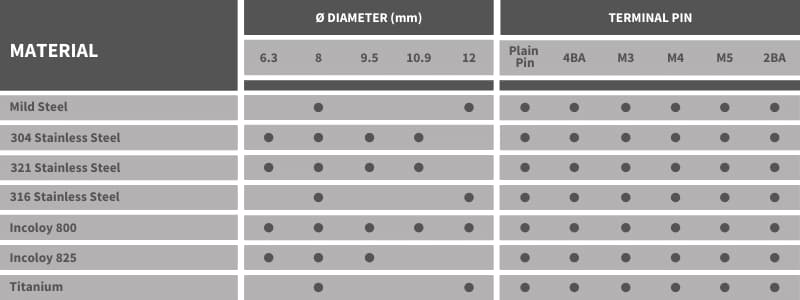

- Elements in 6 material choices in 5 different diameters

- Range of element terminations avaialble from cabled ends to spade terminals

- Variety of fixings available, ranging from brazed ferrules to custom fixing plates

- Bespoke design solutions available on request

- High temperature MgO option availavle for heating up to 800°C

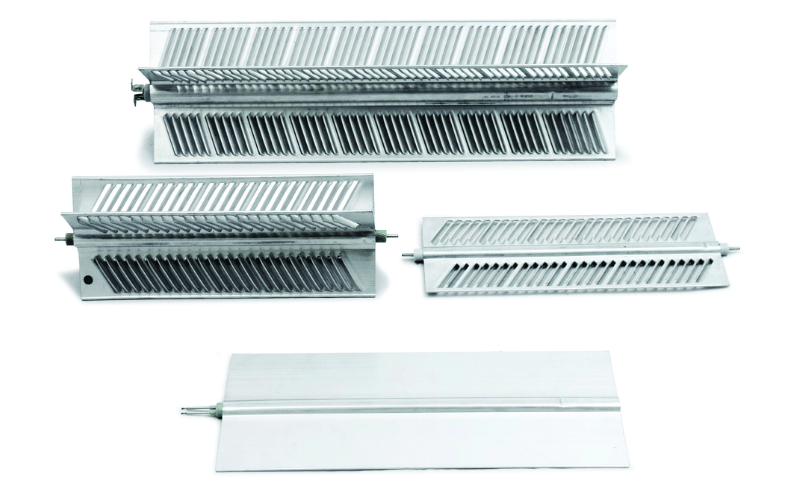

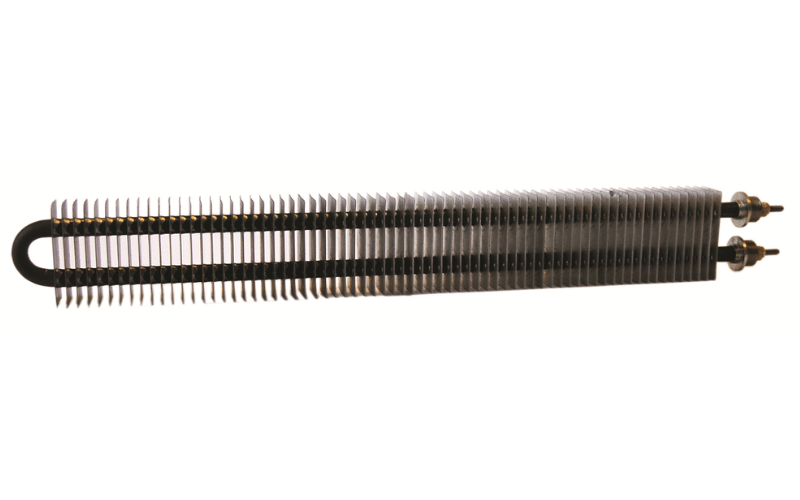

- Finned elements available for air applications

When choosing a tubular element for a certain application there are set parameters that need to be considered. Whilst standard requirements are wattage and voltage, other parameters are sometimes not so obvious. Sheath wattage must also be considered which determines the working surface temperature of the element – this can be critical to the application as many of the media in which our elements are applied will have maximum contact temperatures. Aspects such as electrical and mechanical connections must also be considered at the design stage.

-

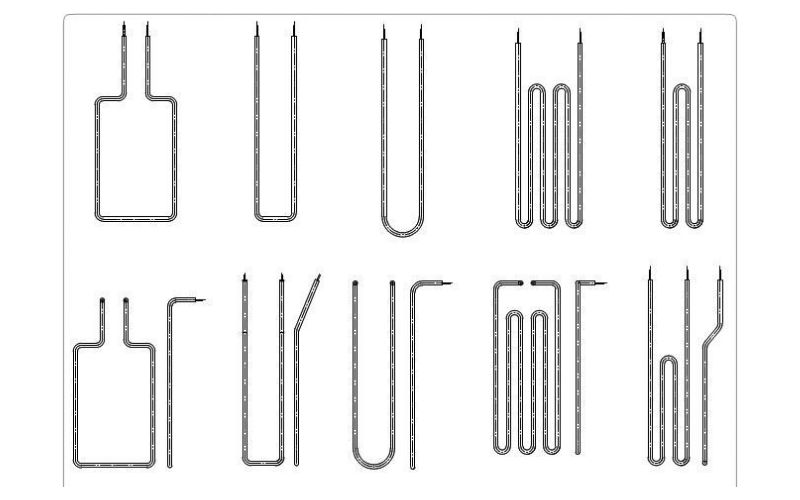

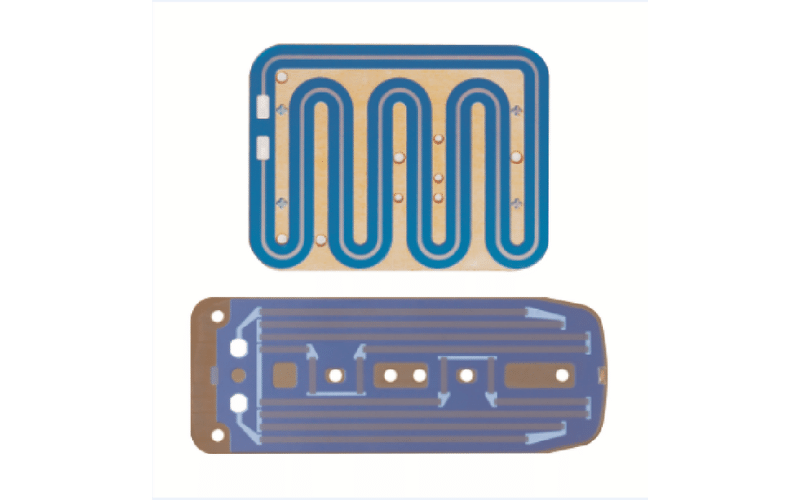

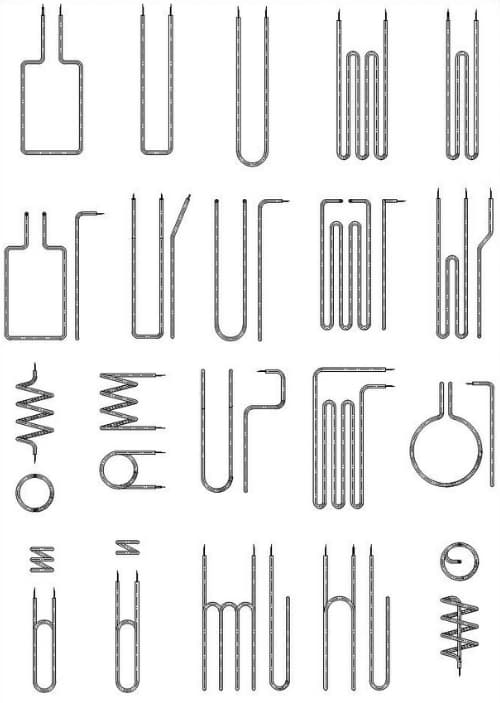

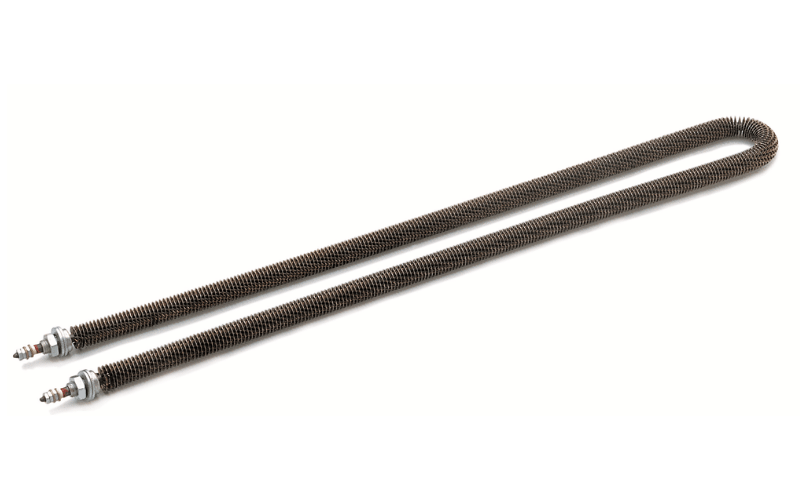

Formed (Tubular) Elements

Applications that require a heat source often have differing application demands such as restricted operating space or very specific local heat zones in shaped objects.

To help solve your specific requirements, Heatrod have a fully trained engineering team who can assist with specification, design and manufacture of tubular elements for your application. Our products are produced using traditional manual methods through to CNC controlled bending machinery.

A small selection of tubular element designs are shown here:

-

Tubular Elements - technical data

-

Finned Elements - technical data

Square Finned Elements Surface enlarged element Ø (brick dim): 8 (50x25), 8.5 (50x25), 10 (70x40) or 14 (80x40) mm

Fin material: Alu zinc or stainless steel

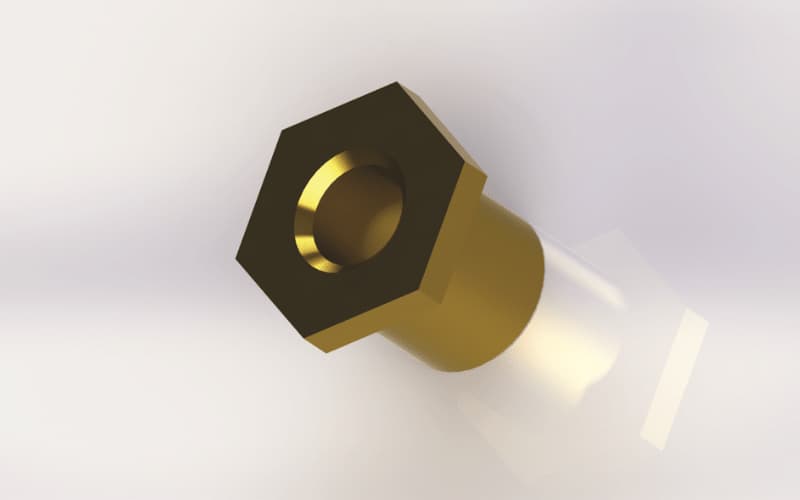

Accessories: Nipples, fixing plates

Finned Elements Surface enlarged element Ø (d/D): 6.4/18, 8/18 8/24, 8.5/22 8.5/28, 10/20 10/26, 12/22 12/28, 14/34 16/32, 18/34 mm

Fin material: SS1160, EN 1.4301

Accessories: Nipples, fixing plates

Tube materials

Mild steel - Grade D

Stainless steel: EN 1.4301, EN 1.4404, EN 1.4541, Incoloy 800, EN 1.4828

Connections

One or two end connection: M34, cables flat pin or acc. to customer specification

Applications: Fixings & Electrical Connections;

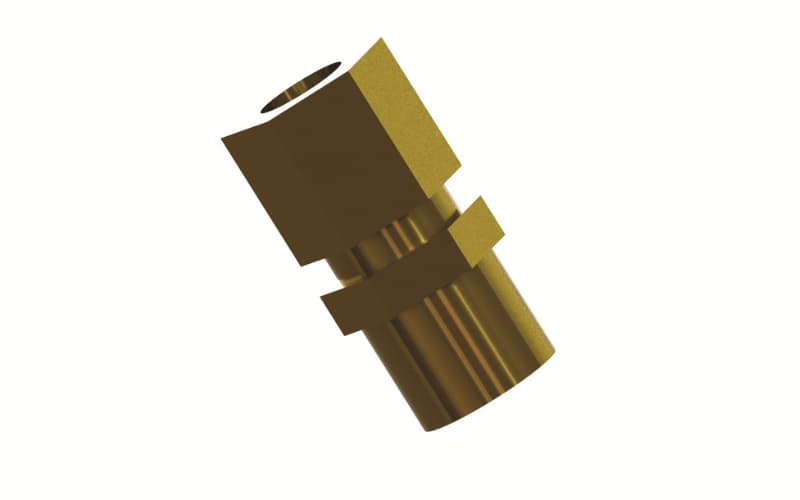

With tubular heaters being so versatile and able to work in a variety of applications, aspects such as electrical connections and a means of fixing the element to an application need to be taken into consideration.

-

Defrost Applications

Electrical Connection

Vulcanised Neoprene 2.5mm Silicone Leads

2.5mm & 5mm Thick Joint available

-

Air Applications

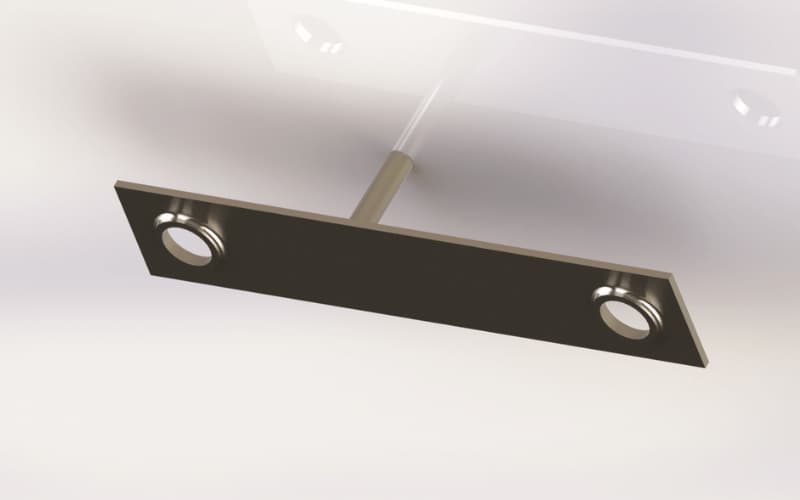

Fixings

¼"BSP Thread x ½" Crimped Collar

¼"BSP Thread x 1" Crimped Collar

3/8"BSP Thread x ¾" Crimped Collar

3/8"BSP Thread x 1" Crimped Collar

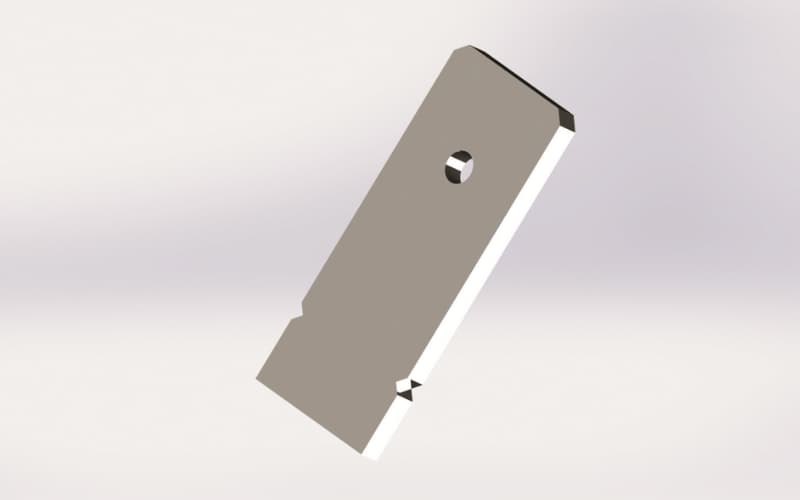

Fixing plates made to suit specific customer requirements

Electrical Connection

Male Spade Terminal

Double Male Spade Terminal

Female Spade Terminal

1.5mm Heat Proof Cable

2.5mm Heat Proof Cable

-

Wet, Oil & Chemical Applications

Fixings

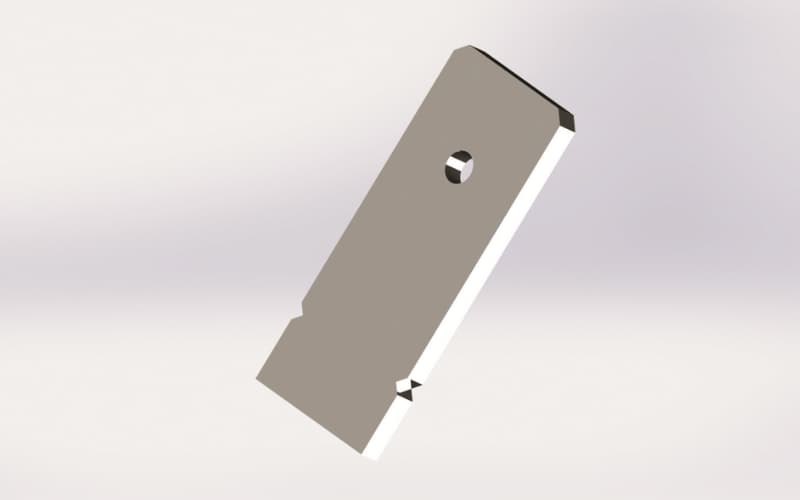

¼"BSP Thread x ½" Brazed

¼"BSP Thread x 1" Brazed

3/8"BSP Thread x ¾" Brazed

3/8"BSP Thread x 1" Brazed

Compression Fitting:

¼"BSP Thread x ½" Brass

3/8"BSP Thread x ½" Brass

¼"BSP Thread x ½" 316SS

3/8"BSP Thread x ½" 316SS

Fixing plates made to suit specific customer requirements - brazed joints

Electrical Connection

Male Spade Terminal

Double Male Spade Terminal

Female Spade Terminal

1.5mm Silicone Cable

2.5mm Silicone Cable

Other cables and fixings available - please enquire.

%201_element.jpg)

%201-industrial.jpg)

%201-projects.jpg)

%20(2)%201500x500.jpg)