Cartridge Heaters & Tool Heating

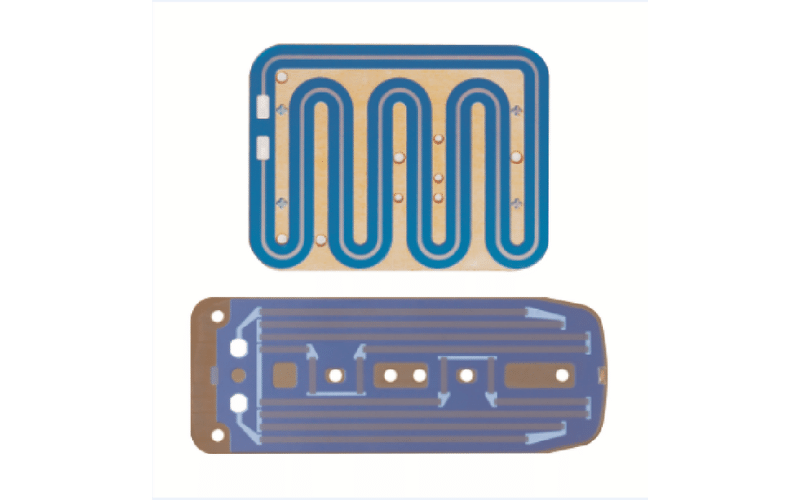

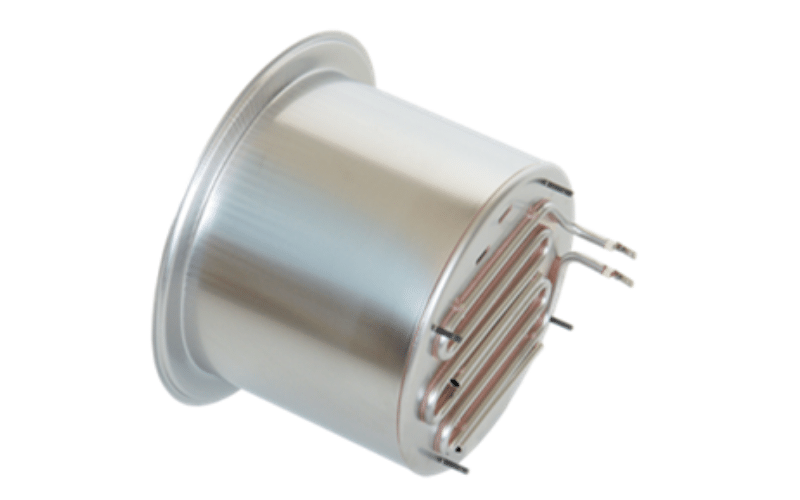

Cartridge Heaters are designed to give high power and temperature outputs for applications in confined Spaces.

Thanks to the design the heat is quickly distributed over the whole surface mantle of the element. The element are designed to withstand high demands of impact resistance and vibration which are often present in the environment where they are required.

Example of Applications

- Machine tool heating

- Plastic extrusion

- Rubber heating

- Foundry application

- Medicine

- Laboratories

Benefits

- High power in confined space

- Impact resistance

- Vibration resistance

- Environment resistance (special coatings)

-

Technical data

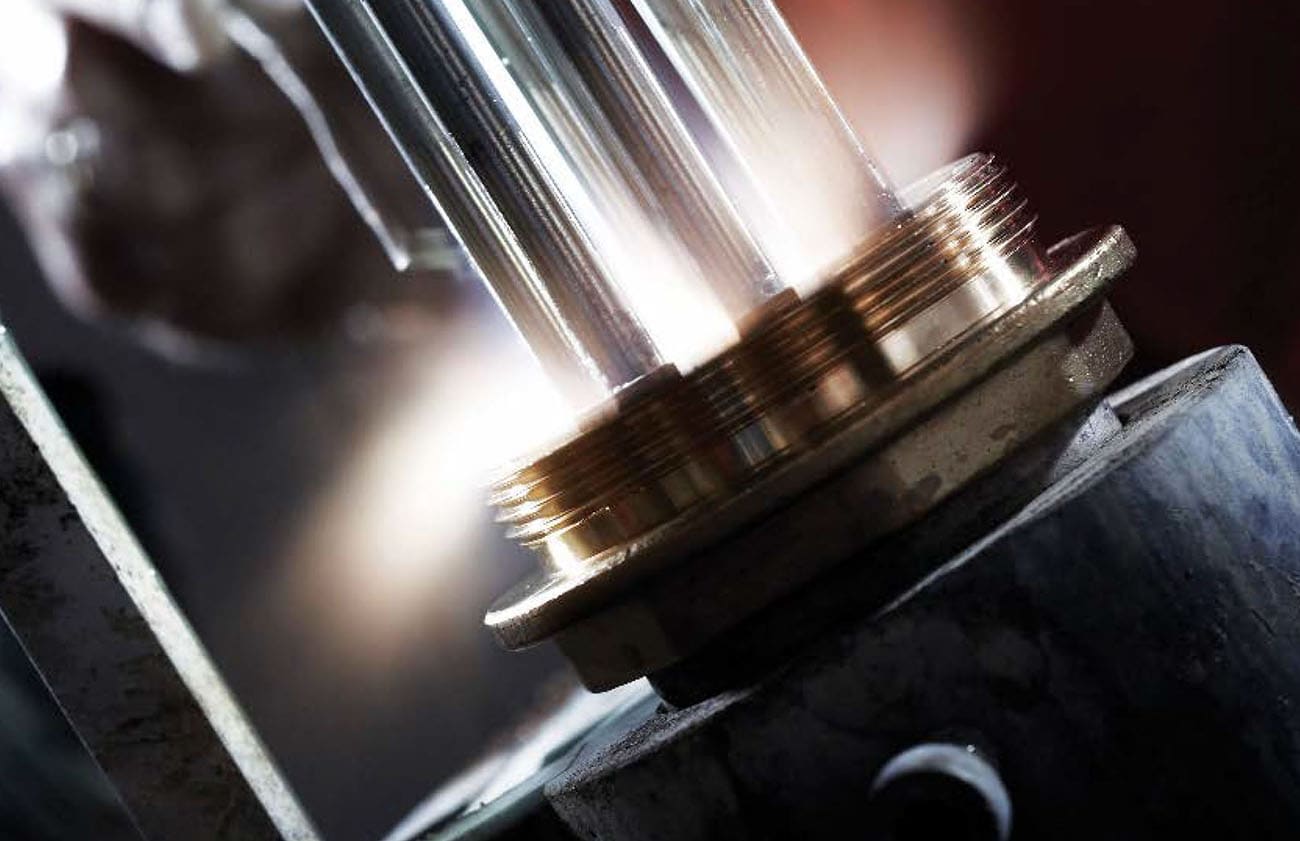

Nozzle Elements are produced with high precision and with high surface loading to meet the high demands of quick and safe heating. During the manufacturing process the element is subject to very high pressure to reach high insulation resistance, good heat transmission without internal voids in the element and a very smooth surface for optional and uniform heat transmission from the total surface of the element. The element is absolutely tight to avoid that for instance melted plastic, oil or gas can leak in.

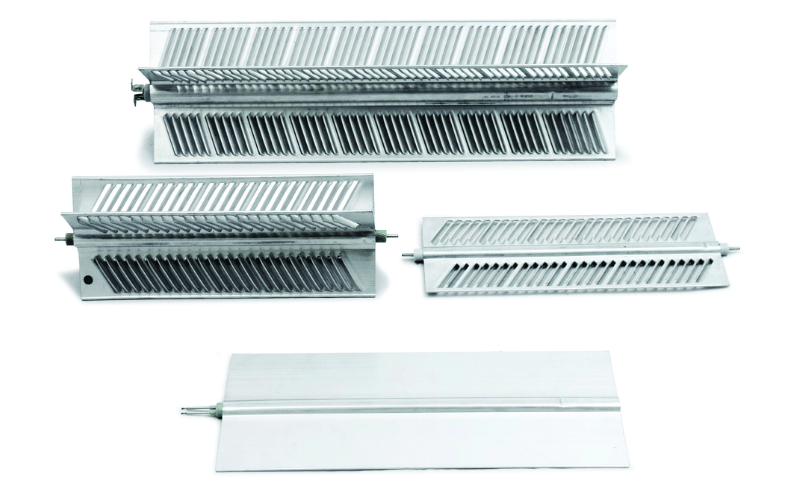

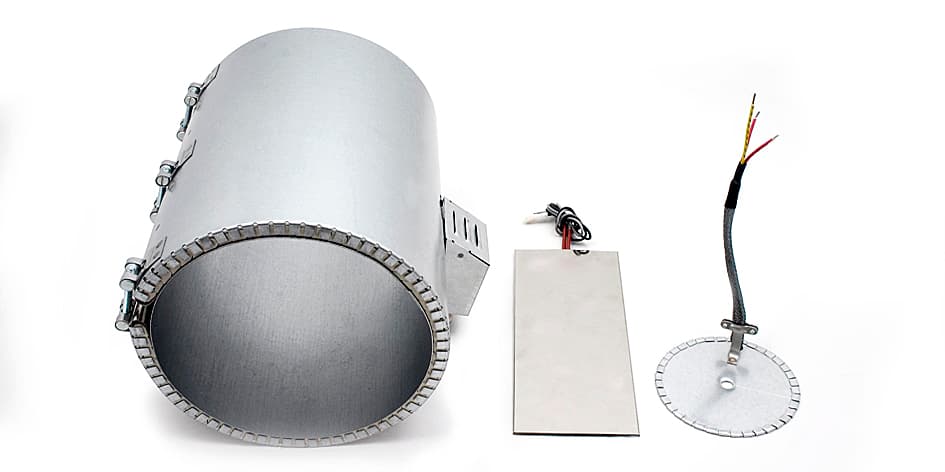

Ring and Band Elements are generally produced and supplied to according to customer specification. Examples application areas are: Injection moulding machines-extruders, containers, tanks, moulds, tools, etc. The design of these units is typically either Micanite or Ceramic with plate casing.

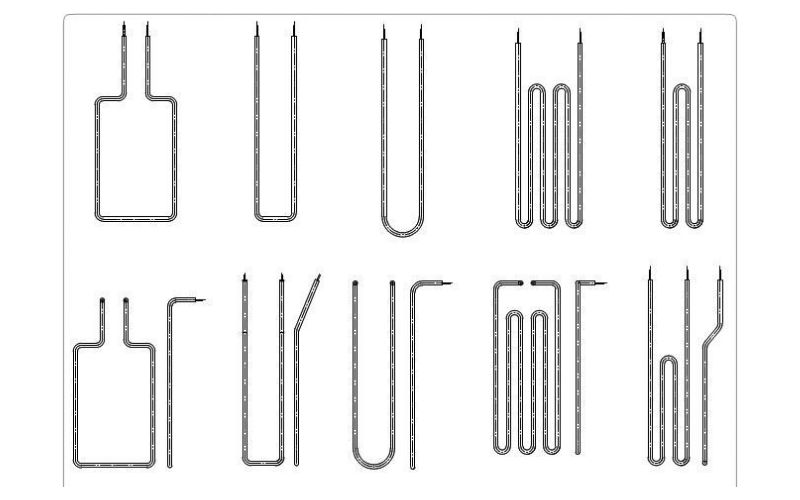

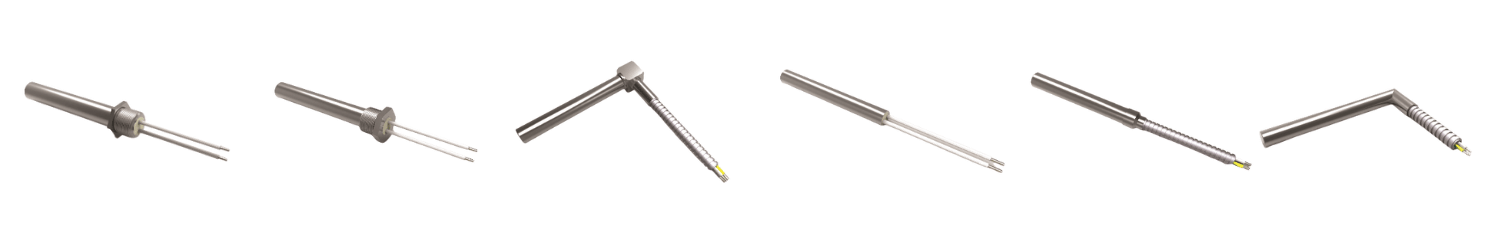

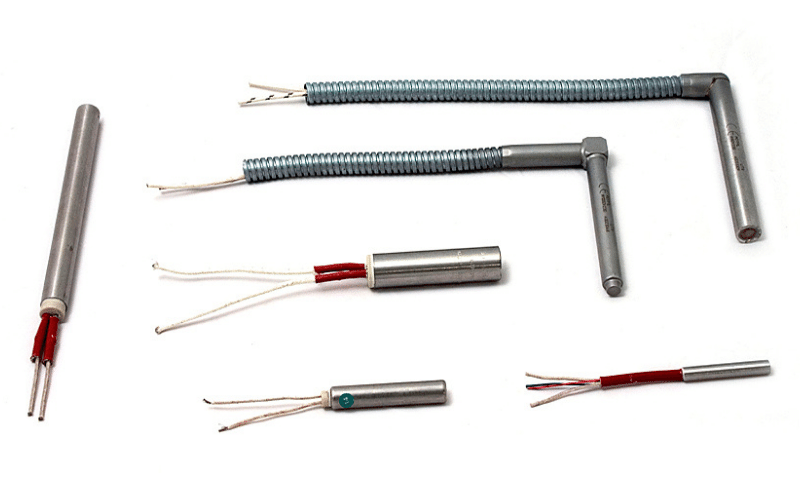

Types: We can supply both UTX and UTC design cartridge heaters in a huge variety of sizes and also to custom specifications.

Material

Stainless steel AISI 321/EN 1.4541

Dimension

Ø 6.5 , 8, 10, 12.5, 16, 20 mm

Inactive section app. 10 mm at the connection end and appr. 5 mm at the other end.Connections

250 mm glass fibre armoured nickel wire

Helical protective hose, zincified steel strip

Wave hose (gas- and liquid tight)

Armoured hose, zincified

Right angle casingAdditional

Reamed holes a smallest tolerance H7

are required (Swedish standard). If a surface load greater that 20W/cm2 is required, individual adjustment is necessary.

Other cables and fixings are available - please enquire.

%201_element.jpg)

%201-industrial.jpg)

%201-projects.jpg)

%20(2)%201500x500.jpg)