Info & Product Examples

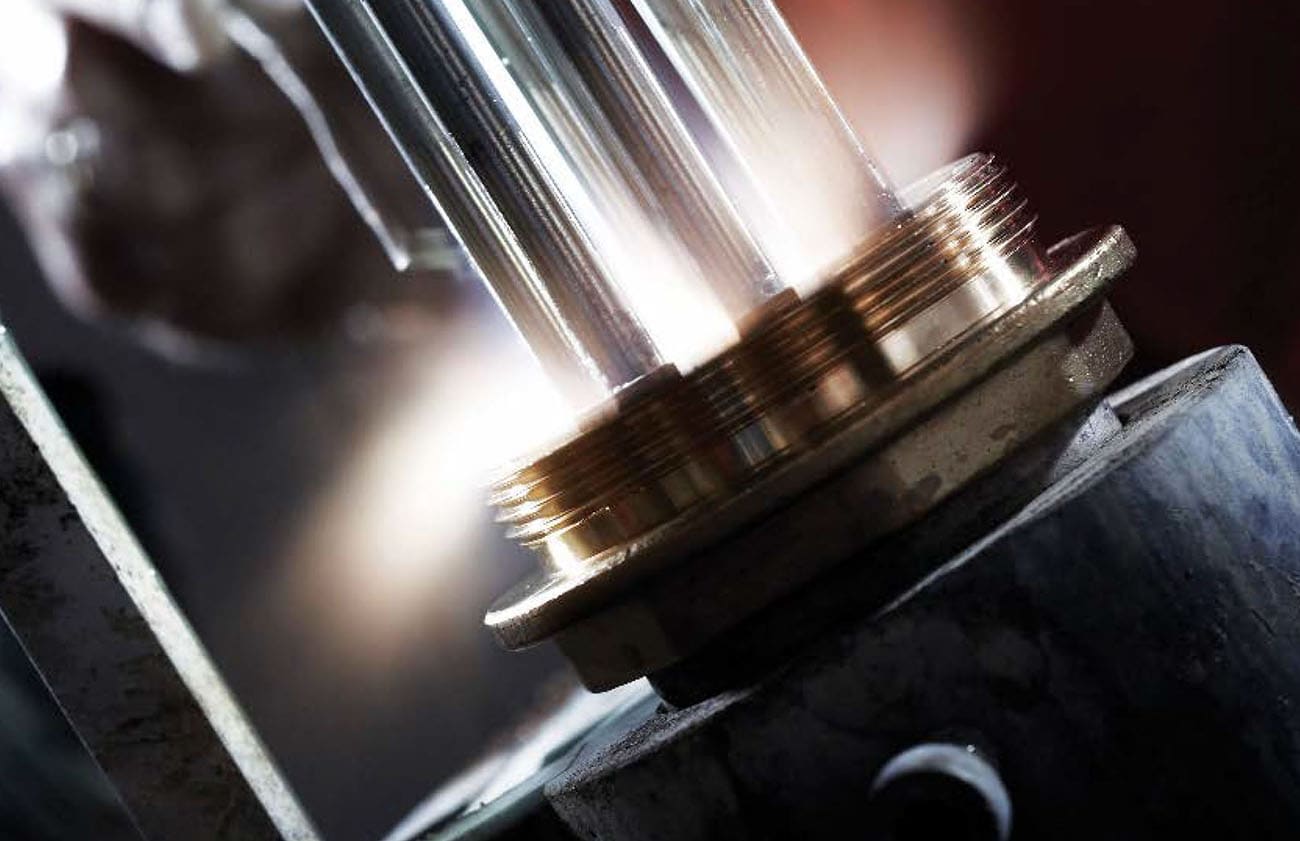

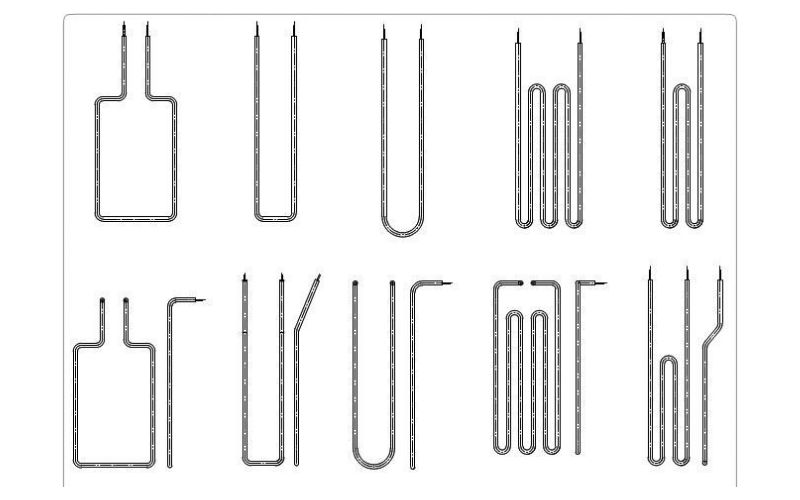

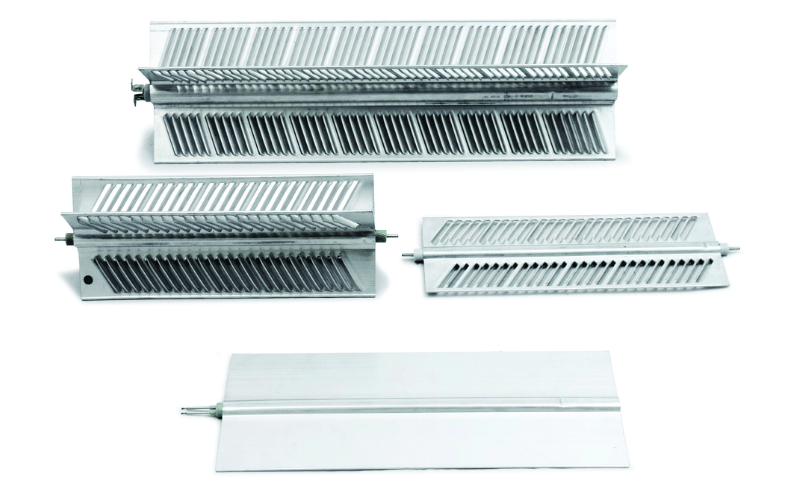

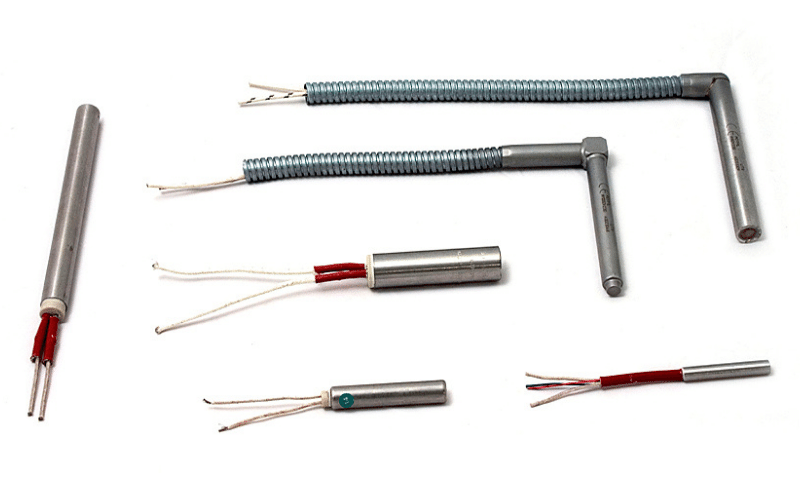

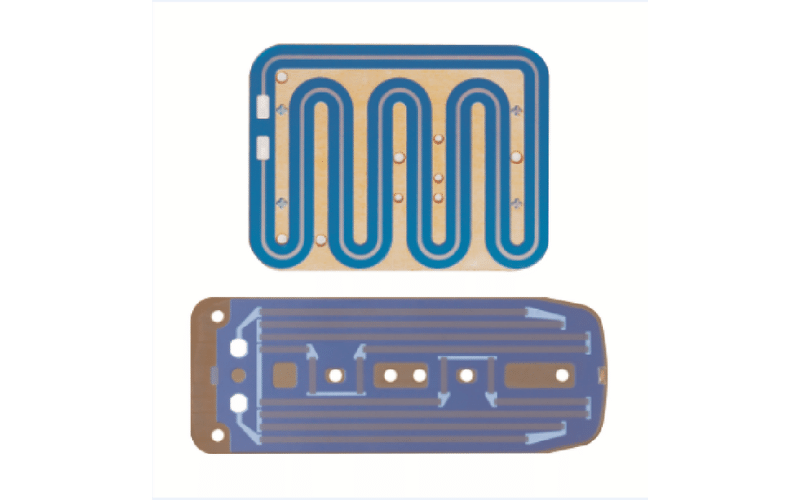

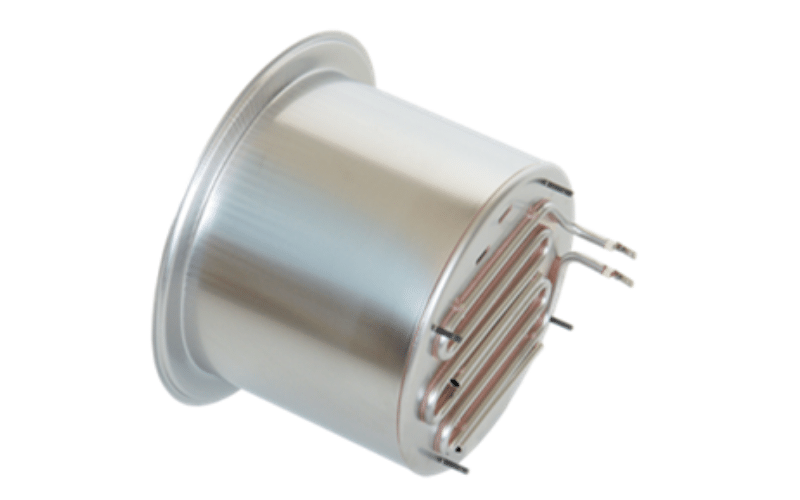

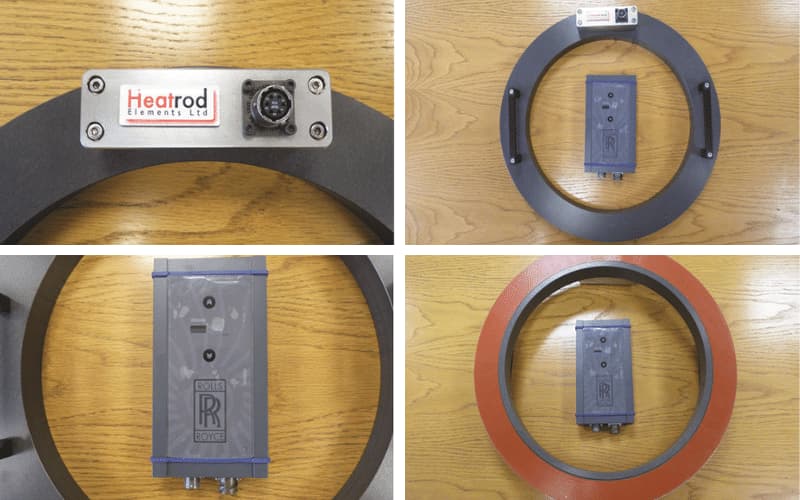

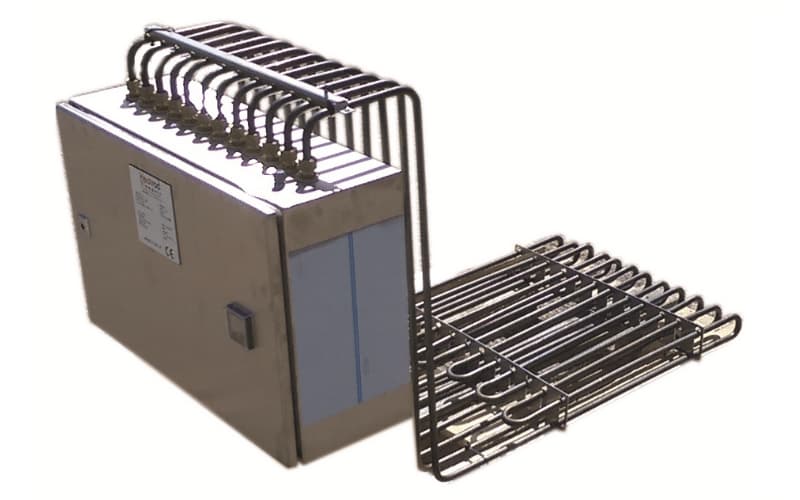

We always find the aerospace industry full of interesting challenges and have worked on projects for both OEMs and end users. Applications for heated tooling is common, particularly when a precision interference fit is required. Also more niche 'on aircraft' solutions have included R&D engineering into very demanding applications particularly when it comes to prevention of moisture ingress which is a key topic for heating elements. Our team of application engineers are trained to be able to consult with our customers in solving their heating challenges and to be able to provide technically and commercially competitive solutions to our customers. Add to this our centre of competence in Sweden and our ability to manufacture and install locally and you have access to a full project delivery team ready to support you.

Please see below examples of our Aerospace projects

%201_element.jpg)

%201-industrial.jpg)

%201-projects.jpg)

%20(2)%201500x500.jpg)