Vacuum Brazing Elements

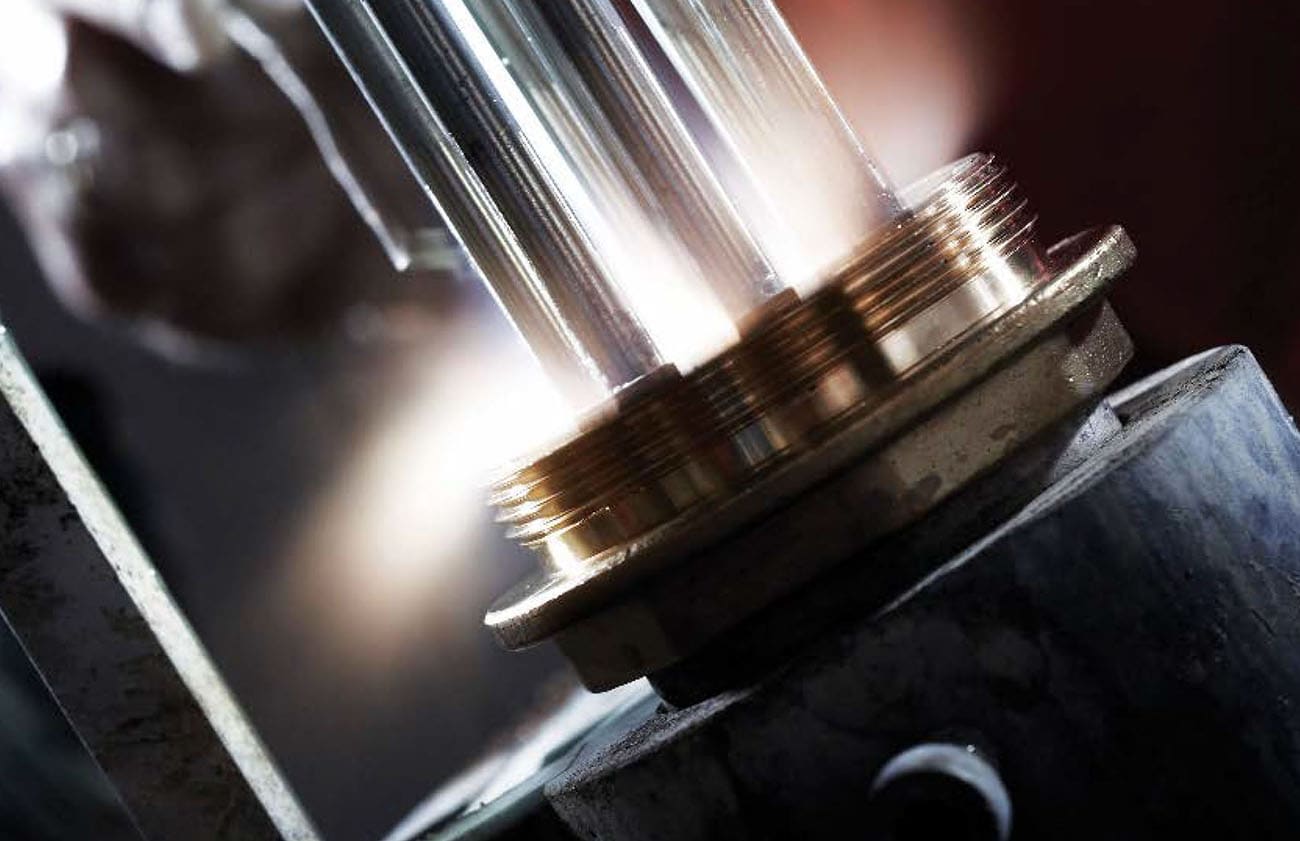

The vacuum brazing process is a unique method to join parts. During the brazing process, the braze material melts and flows into a joint by capillary force, creating a gas-tight seal. Brazing temperatures are between 900-1200 degrees under vacuum of one millionth of atmospheric pressure (<0,001 mbar).

Major advantages with vacuum brazing include; unchanged structure of the brazed units, good mechanical strength of the brazed seam, corrosion resistance and cleanliness. Vacuum brazing also enables uniform quality of brazed seams.

Vacuum brazing does not require any flux or other additives and therefore no cleaning or passivating processes are required. Vacuum treatment ensures that brazed units do not react with the ambient gases, ensuring high quality seam.

Vacuum technology enables brazing of the most demanding assemblies and is a popular method in space and aviation technology and other clinically demanding applications, including vending machines.

Example of Applications

- Coffee machines/boilers

- Laboratory/medical

- Heat pumps

- Flow through heaters

- Tempering units

Benefits

- High quality brazed joints

- Clean process, no emissions, no need for fluxes

- Suitable for mass production

- Different products can be brazed simultaneously

- Complex joints are easy to braze

- Technique is used especially in aviation and space industries & in clinically demanding applications

Our sister company Loval has several demanding product groups and customer segments where vacuum brazing with different stainless steel grades and brazing filler metals is the preferred brazing method. Highly developed vacuum brazing technology is Loval's special strength.

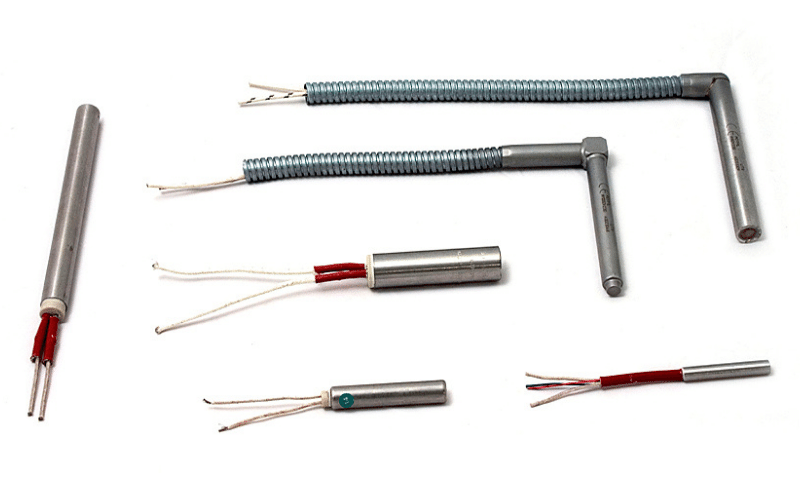

Other cables & fixings are available - please enquire.

Products

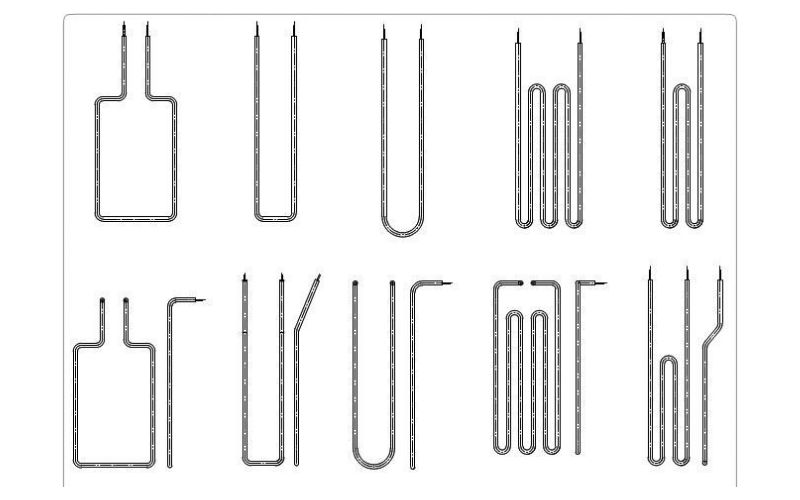

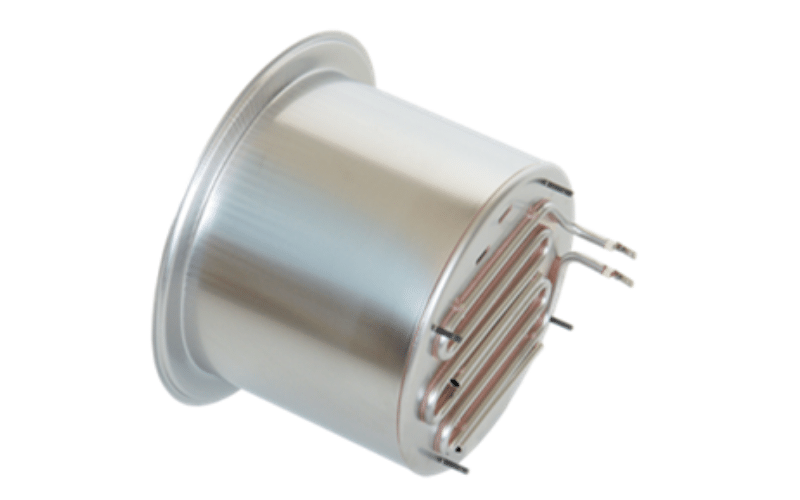

Pipe Heat Exchangers

Our sister company, Loval, designs and produces a wide range of pipe heat exchangers for various heat transfer applications. The Loval Pipe Heat Exhanger is a combination of different pipe diameters and connectors. Dimensioning is based on required power and flow rate. Materials can be chosen from unalloyed and alloyed steels.

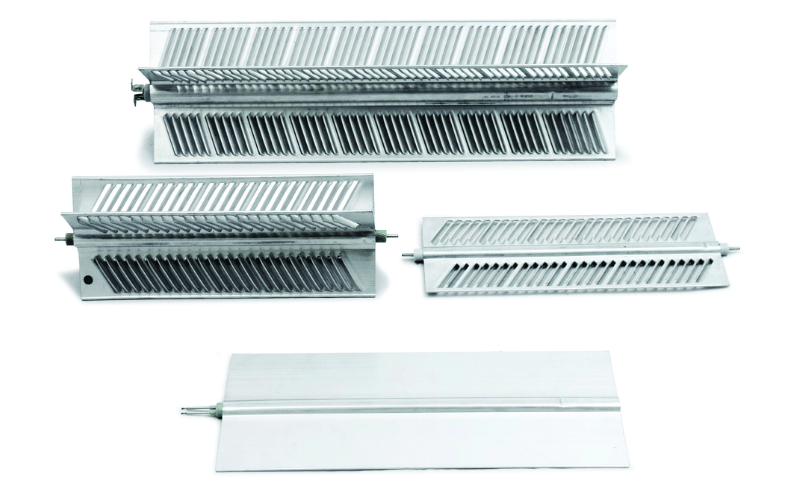

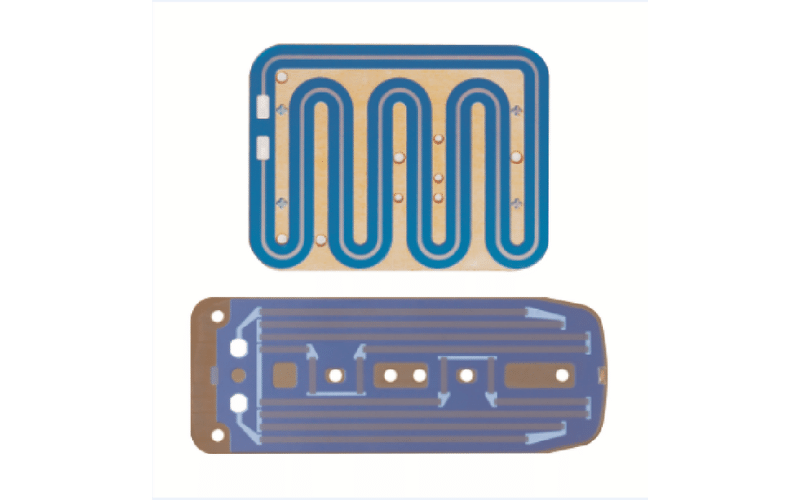

Plate Heat Exchangers

Plate heat exchangers HPA-52A are especially designed as condensers or evaporators for heat pumps. High quality finishing and tightness are crucial for this kind of products. Loval vacuum brazed plate heat exchangers are of a very high quality and among the top products on the market.

Manifolds

Our purely stainless vacuum brazed construction means outstanding corrosion resistance. Tailored solutions e.g. manifolds for coffee machines made to measure guarantee the best results for everyday use.

%201_element.jpg)

%201-industrial.jpg)

%201-projects.jpg)

%20(2)%201500x500.jpg)