Published date:

Nautilus Heat Exchangers: Proven Performance Across Global Industries

The Nautilus pompilius, a marine organism often referred to as a "living fossil," has remained virtually unchanged for over 400 million years. Its natural buoyancy system, comprised of fluid-regulated chambers exemplifies efficient, adaptive design.

Engineered for the most demanding applications

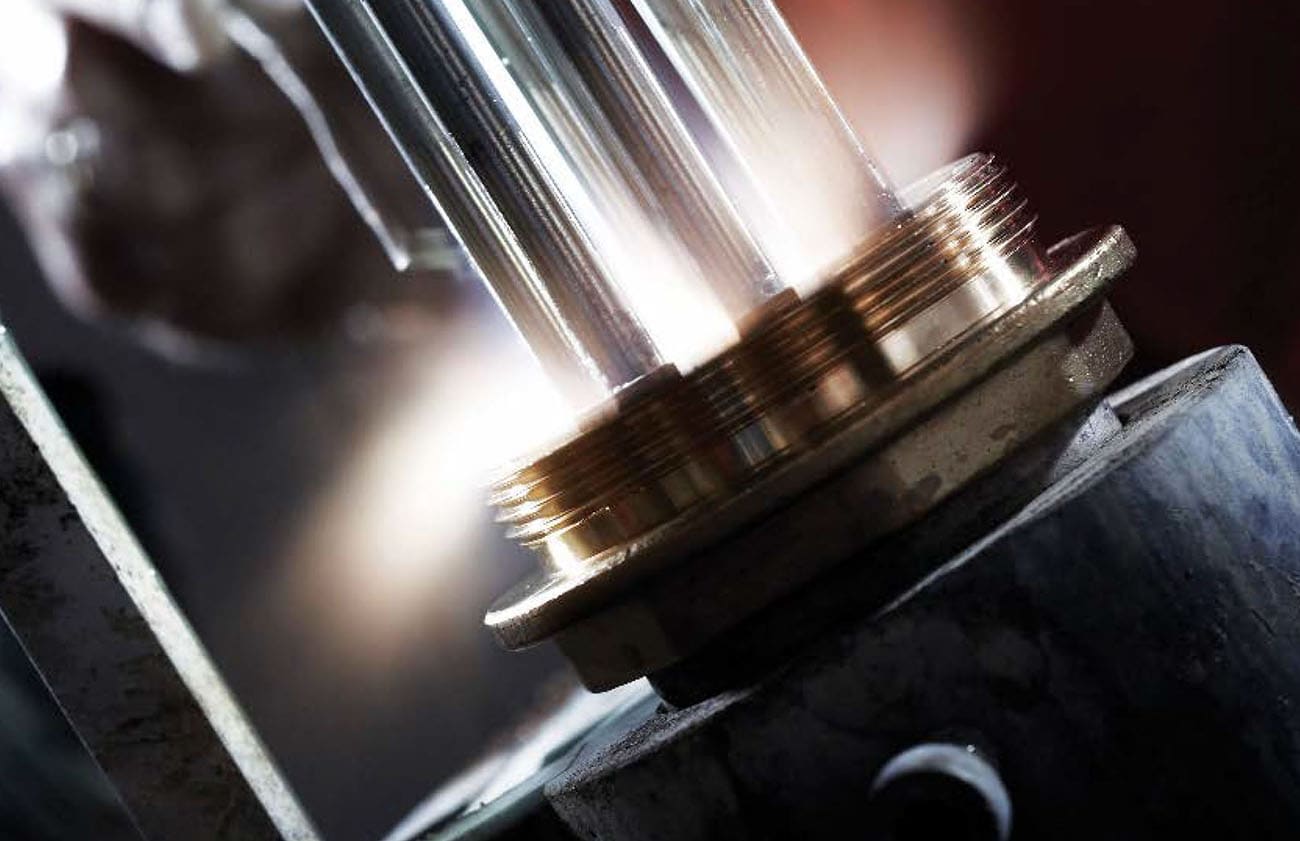

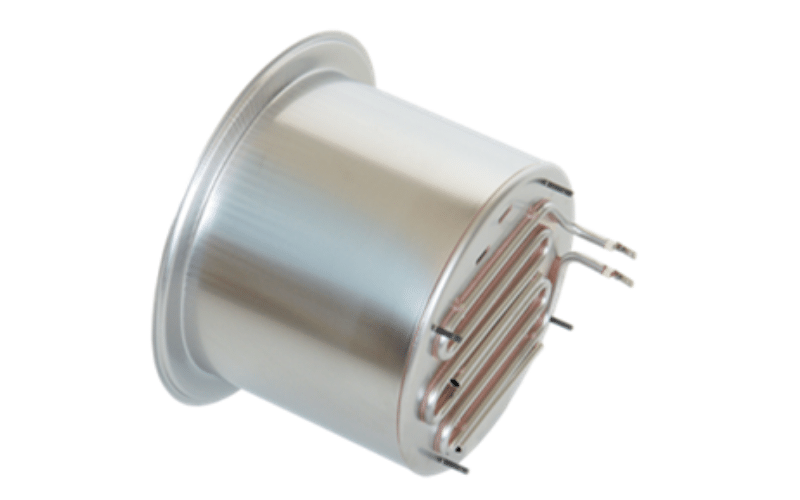

The Braude Nautilus Heat Exchanger is designed for industries where conventional materials fail under pressure. Its robust, non-corrodable construction and exceptional thermal performance make it the preferred solution in environments characterised by aggressive chemicals, high temperatures, and continuous operation.

Applications across key sectors

Chemical Processing and Surface Treatment

Nautilus units are widely deployed in facilities handling caustic and acidic solutions such as hydrochloric, hydrofluoric, nitric, and sulphuric acids. Common applications include:

- Pickling lines for mild and stainless steel.

- Electroplating and anodising operations requiring precise thermal control.

- Etching and cleaning baths in semiconductor and electronics manufacturing.

Galvanising and Metal finishing

Trusted in hot-dip galvanising and pre-treatment processes, Nautilus excels in:

- Structural steel fabrication (e.g., crash barriers, beams, rebar).

- Automotive component coating for corrosion resistance.

- Aerospace alloy preparation.

- Iconic decorative projects, such as The Kelpies in Scotland.

Jewellery, Precious Metals & Plating

In high-purity applications, Nautilus ensures contamination-free heating for:

- Gold, silver, and rhodium plating.

- Cleaning of diamonds and precious stones using aggressive solvents.

Aerospace & Defence

Supporting environmentally conscious and high-precision processes:

- Tartaric Sulphuric Acid Anodising (TSA) and Tartaric Acid Anodising (TAA).

- Titanium and aluminium surface treatments.

- Component cleaning for turbine blades and airframe parts.

Heavy Industry & Manufacturing

Nautilus is a staple in:

- Steel mills for coil pickling and acid regeneration.

- Battery production for electrolyte heating.

- Pharmaceutical and biotech environments requiring non-metallic, sterile systems.

Why Nautilus Matters

In chemically aggressive and high-demand environments, operators face persistent challenges such as equipment corrosion, inconsistent heating, and costly downtime. The Nautilus Heat Exchanger addresses these with:

- Exceptional durability in corrosive and high-stress conditions.

- Minimal maintenance, thanks to its fully non-metallic, corrosion-resistant design.

- Reliable thermal performance that supports continuous, high-efficiency production.

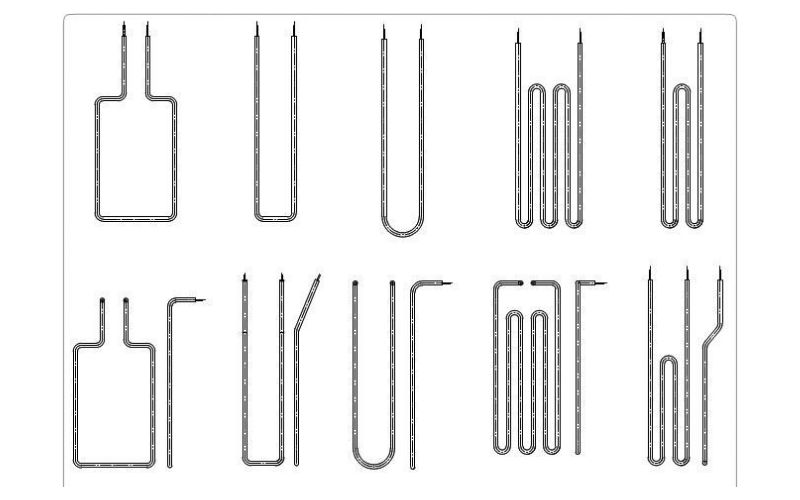

- Custom-engineered configurations for integration into confined or complex tank geometries.

- Seamless retrofitting, enabling direct replacement of outdated metal or carbon block systems without major redesigns.

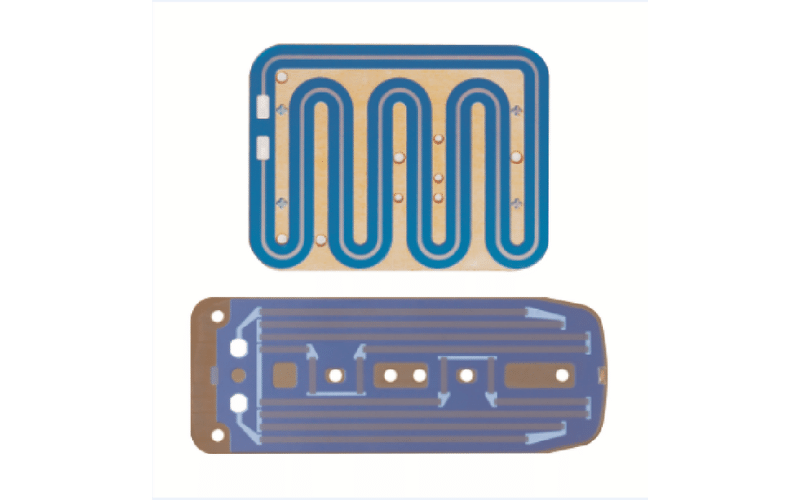

Key Technical Features

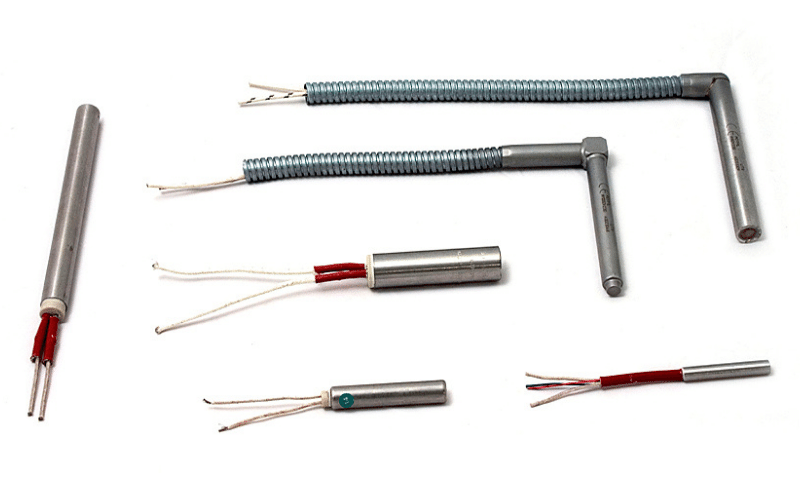

- Constructed from high-purity, fully tested fluoropolymers (PTFE) for superior chemical and thermal resistance.

- Thermally versatile, compatible with steam, hot water, thermal fluids, or chilled water.

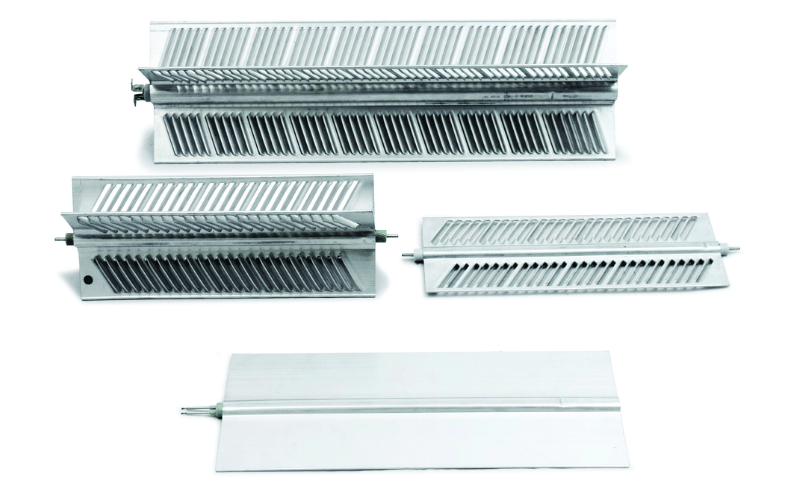

- Scalable output, ranging from 20 kW to 400 kW per unit, adaptable to both compact and large-scale systems.

- Flexible design architecture, allowing installation in hard-to-reach or space-constrained areas.

- Retrofit-ready, simplifying upgrades from legacy systems with minimal disruption.

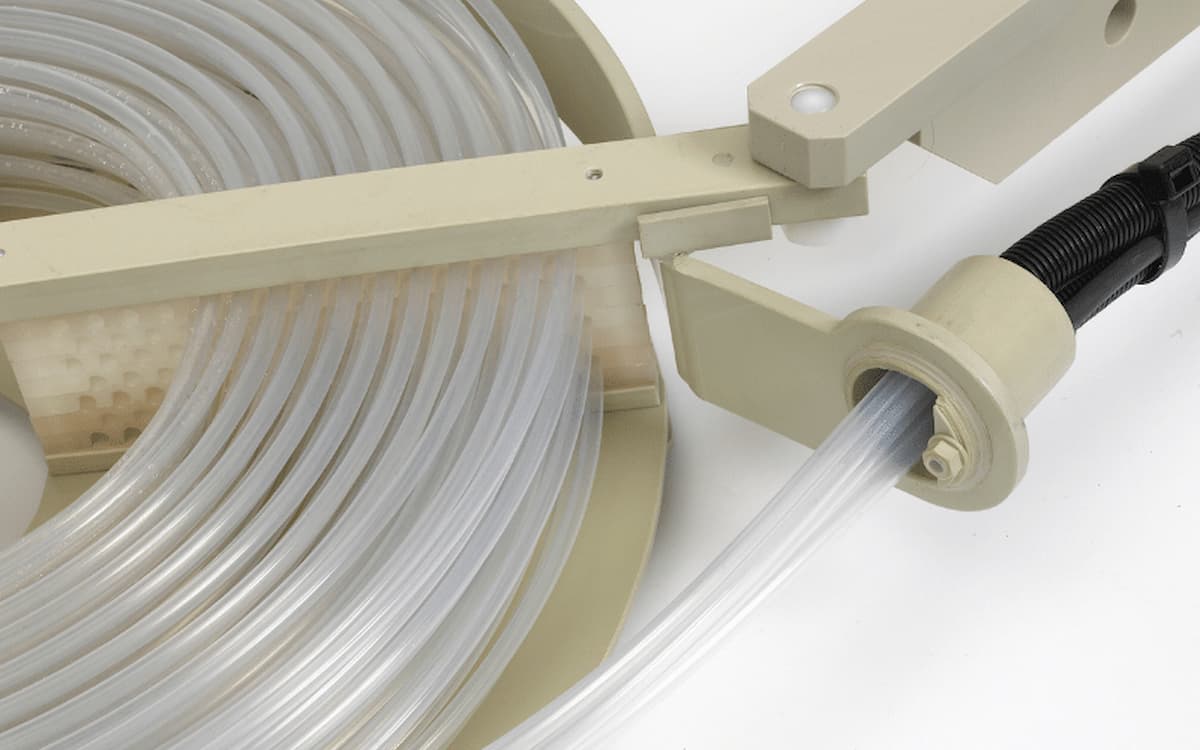

Next-Generation Cooling: Nautilus Fluorochill

To meet the evolving demands of modern manufacturing, Braude developed the Nautilus Fluorochill—a compact, high-efficiency cooling solution that builds on the legacy of the original Nautilus.

Fluorochill Advantages

- 20% higher cooling efficiency, ideal for high-throughput operations.

- 20% smaller footprint, optimised for space-limited installations.

- Up to 30% cost savings, enabled by streamlined manufacturing processes.

- Environmentally responsible, supporting sustainable alternatives like Tartaric Acid Anodising.

Global Reach, Industry-Specific Expertise

At Braude, we recognise that industrial challenges vary by sector and geography. That’s why we continue to expand our portfolio of tailored solutions, backed by decades of technical expertise.

Our products are trusted not only across the UK but also in major global markets including India, the UAE, and other leading industrial economies—demonstrating the universal reliability and adaptability of the Nautilus range.

Let's Talk

Contact us to discover how the Braude Nautilus Heat Exchanger can enhance your process performance and operational resilience.

%201_element.jpg)

%201-industrial.jpg)

%201-projects.jpg)

%20(2)%201500x500.jpg)