Published date:

Keep your liquid levels under control this winter

Without sensitive and carefully designed monitoring equipment even the most robust and well-built industrial machinery or processes can go catastrophically awry.

Braude have a range of products to help you ensure your tanks are working safely and efficiently.

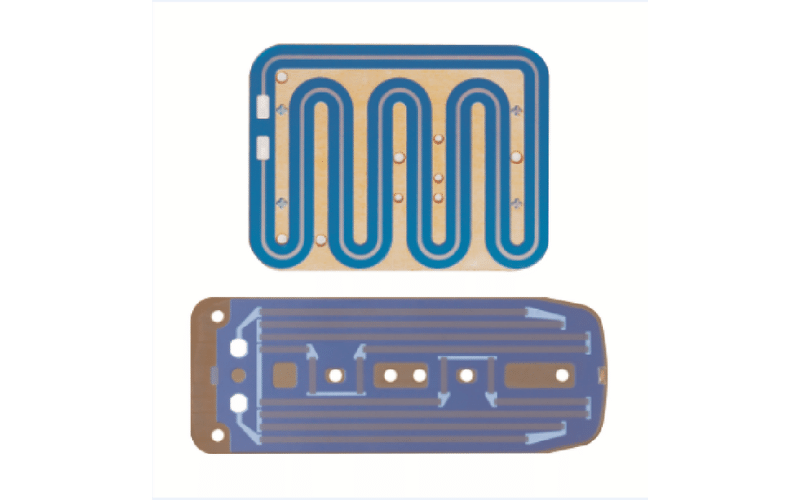

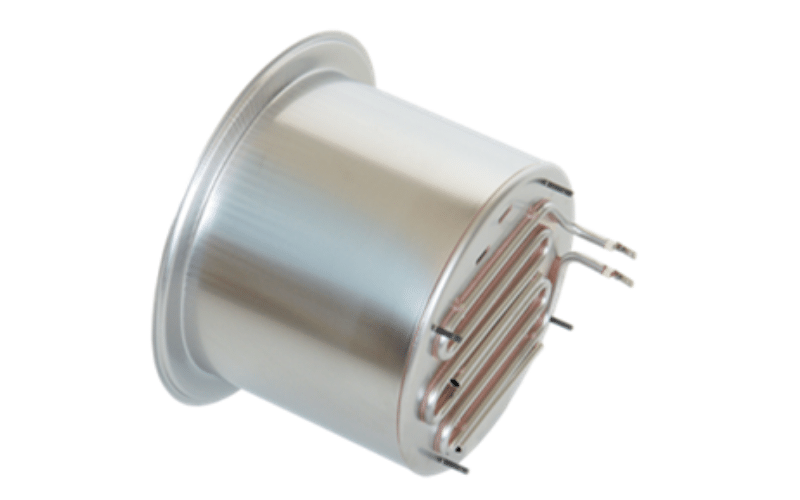

The Braude Tankmaster MP is a combined temperature and level controller. It is supplied complete with non-corrodable temperature and level sensors for use in the corrosive solutions found throughout the Finishing industry.

The controller is designed for surface mounting and sealed to IP65 so it is suitable for use close to the point of use providing an easily read display for the operator of tank conditions. It provides a display of the set point as well as the temperature of the bath and has no external buttons or knobs so preventing the accidental alteration of the setting.

Features include:

- Secondary set point either from a single or an ancillary probe.

- Drop back facility to enable a lower set point temperature to be selected, which is ideal to allow maintenance of a tank over a weekend.

- Can be set by the end user or alternatively can be preset in the factory prior to despatch

Thermaster and Levelmaster controllers are also available from Braude and all probes are interchangeable with the Tankmaster.

Thermaster TS - Plating and process tanks need reliable control and the Braude Thermaster TS has been produced specifically for those applications. The Thermaster TS is perfect for sending data to a PLC which can be set programmed to monitor and control the temperature of the process tank. It can easily be linked to a multiple tank system and monitored from one central, often remote, location.

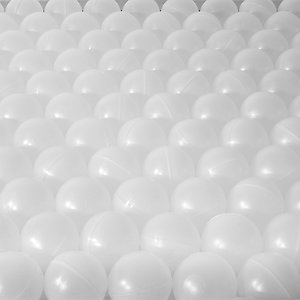

Frogspawn Thermal Insulation Spheres form a floating blanket ideal for use on the top of open process tanks, giving a physical cover of 91% to provide a continuous insulating layer. The air inside the hollow spheres and the air pockets between them provides insulation but still allows workloads like jigs and components to easily pass through the layer. Two main advantages are:

- Savings in heat loss of up to 75%, depending on temperature conditions

- Savings in vapour loss of up to 90%, reducing corrosive effects on structure of plant and buildings.

All products are backed up by Braude’s experience of many years manufacturing and supplying equipment for arduous environments and are provided with a full 12 month guarantee.

To find out more call our sales team on +44 (0) 1252 876123 or send us an email [email protected]

%201_element.jpg)

%201-industrial.jpg)

%201-projects.jpg)

%20(2)%201500x500.jpg)