Published date:

Innovative Heating Solution for Corrosive Pickling Line

When a new wire rod pickling line was commissioned at a major rod mill in Sheffield, the design team encountered a significant engineering challenge: how to effectively heat tanks containing highly aggressive and corrosive chemical solutions.

These tanks held a mixture of hydrofluoric and sulphuric acids operating at 60°C, along with large amounts of scale and sludge—by-products of the pickling process.

Traditional heating methods, such as serpentines and plate heaters, were unsuitable due to their susceptibility to rapid chemical degradation and the risk of mechanical damage from the heavy coils of rods processed in each batch. A robust, corrosion-resistant, and low-maintenance solution was essential.

The Solution

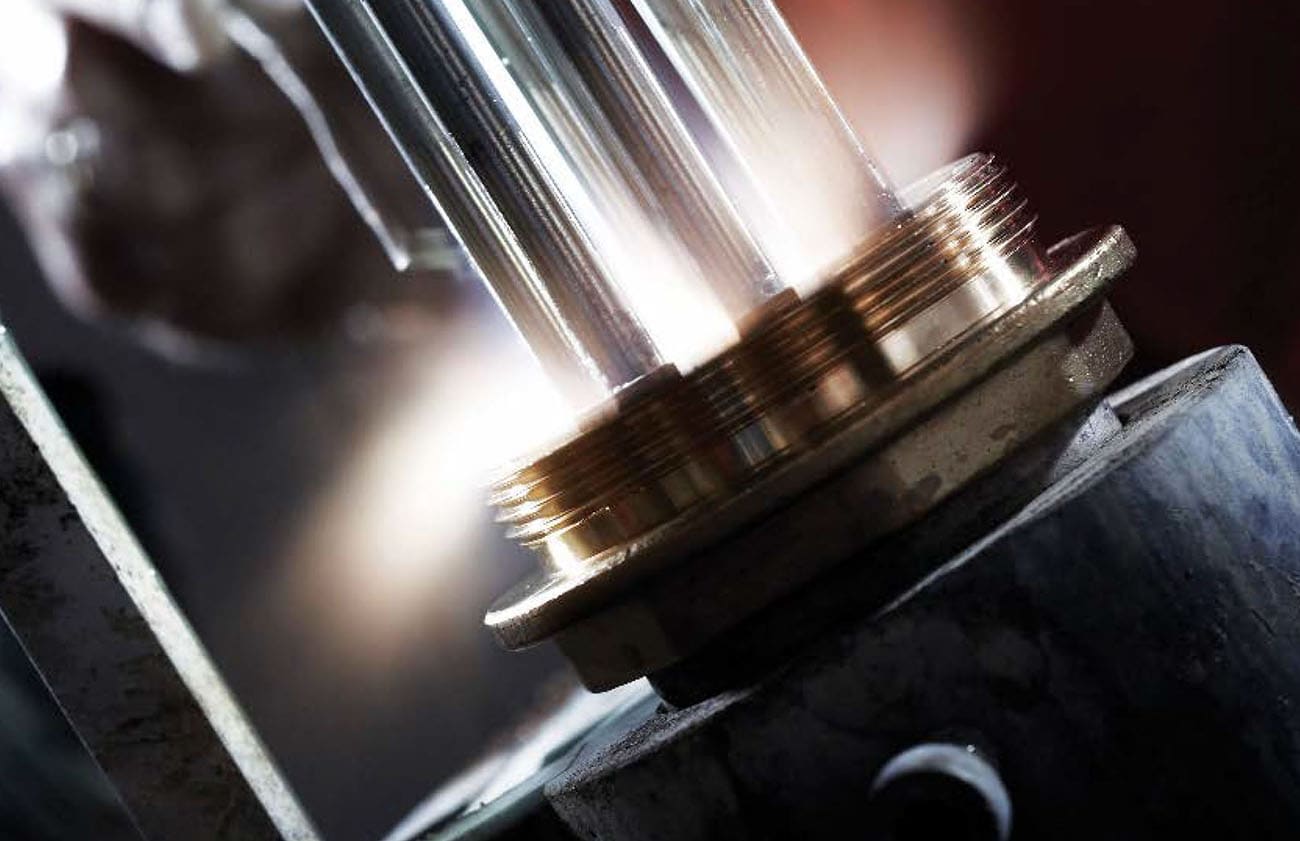

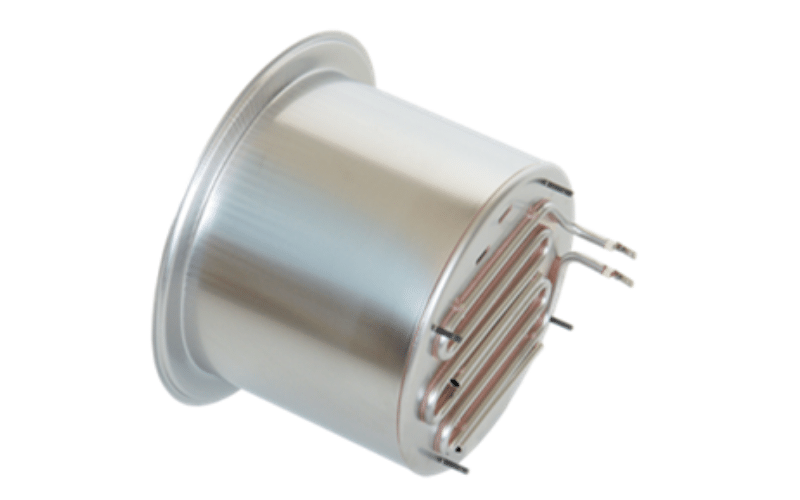

We proposed the Jet Stream External Heating System, integrated with a low-pressure hot water supply. This innovative system provided a safe and efficient method of heating the pickling solution while keeping all critical components external to the tank.

The installation proved highly successful, delivering reliable performance and operational efficiency. Following this success, the Jet Stream system has become the preferred solution for subsequent installations at the site.

Key Advantages of the Jet Stream System

- External Installation: Positioned adjacent to the process tank, the Jet Stream unit maximises internal tank space, eliminating obstructions and allowing full utilisation of the tank for processing.

- Protection from Damage: With the heating element located outside the tank, the system is safeguarded against impact from heavy and awkward workloads typical in steel processing.

- Simplified Maintenance: The freestanding design allows for easy access and servicing without the need to drain or dispose of costly chemical solutions—resulting in significant savings in both chemicals and downtime.

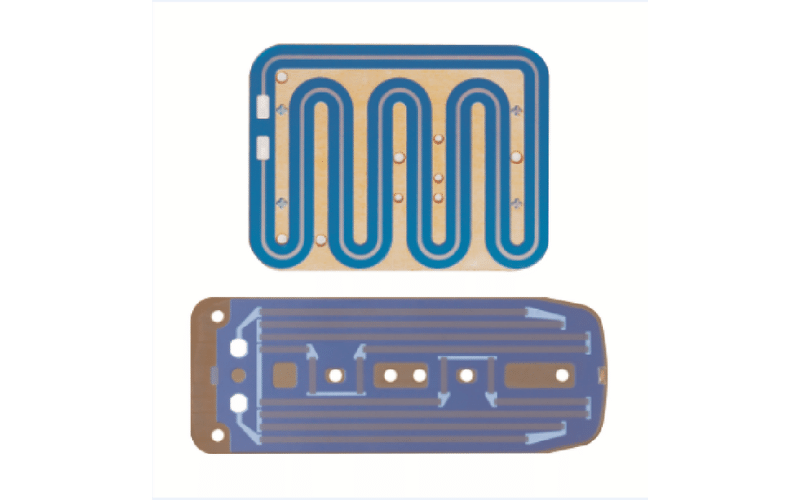

- Corrosion-Resistant Construction: Manufactured from high-integrity polymers, the system is engineered to withstand even the most aggressive chemical environments.

- Efficient Heat Transfer: Continuous recirculation of the process liquid through the Jet Stream unit ensures optimal heat exchange and uniform temperature distribution throughout the tank.

- High Capacity Output: A single Jet Stream unit delivers sufficient heat for high-volume batch pickling and other continuous production processes.

Braude’s Broader Capabilities

With decades of experience in managing the complexities of highly corrosive chemical processes, Braude also offers a comprehensive range of complementary equipment, including:

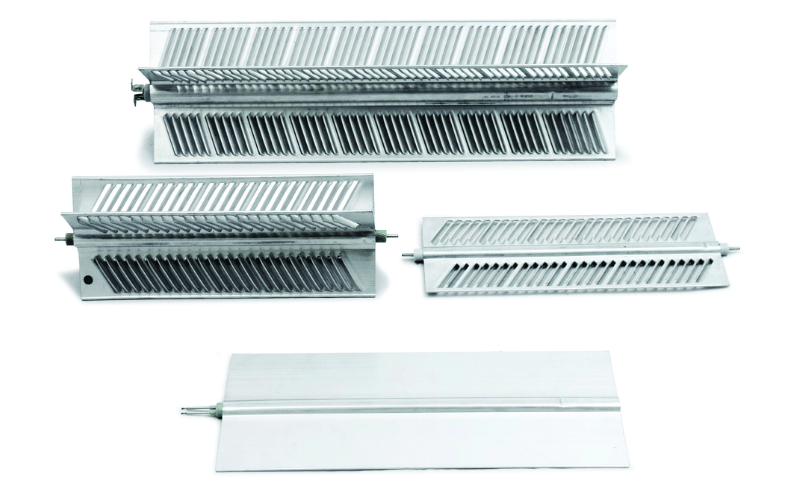

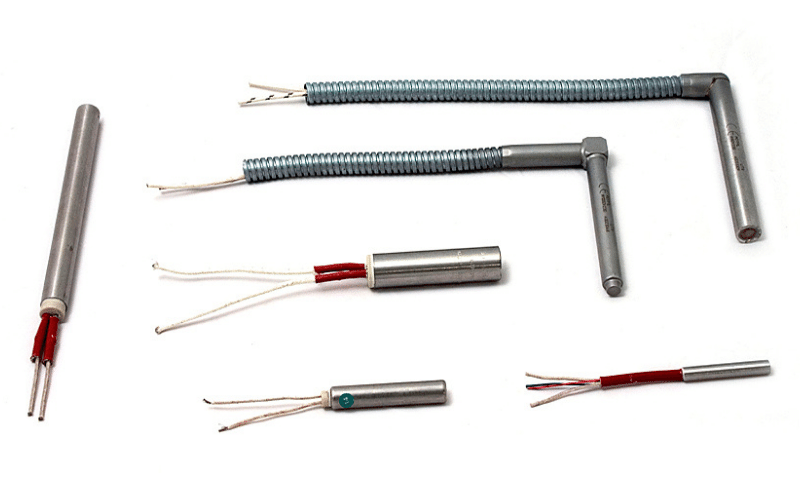

- Polaris Popular & Modular non-corrodible electric immersion heaters

- HRDc, Tankmaster, Thermaster, and Levelmaster process controllers

- Electrojet & Electric Jet Stream heat exchangers for large-scale applications

- Chemical transfer pumps

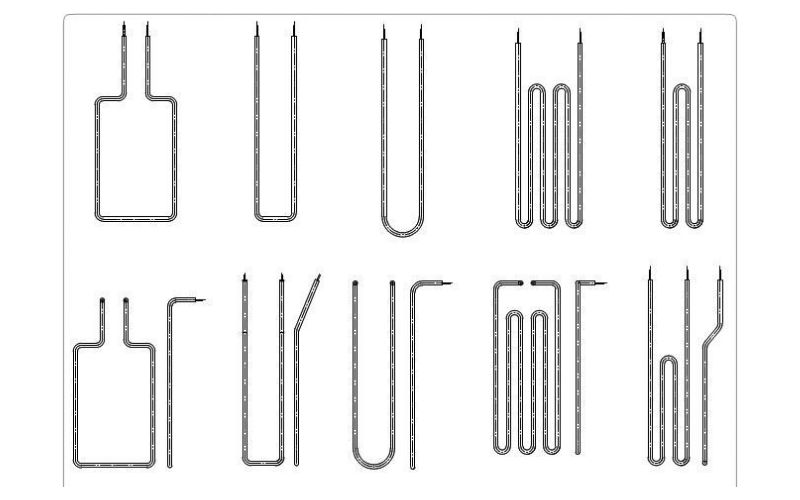

Backer Heatrod offer design, production and supply of electric heating for the process industry, providing products meeting all relevant standards and tests. Certifying products to customer specifications, we design, develop and manufacture all types of systems for electrical heating of gases, liquids, vapours and solids.

%201_element.jpg)

%201-industrial.jpg)

%201-projects.jpg)

%20(2)%201500x500.jpg)