Published date:

Heating and control systems for Cleanrooms in semiconductor manufacturing

Following the disruption to supply chains both during and after the lockdowns caused by COVID-19, we have focused on the semiconductor sector to explore how our expertise can be of service.

The Challenge

Semiconductor manufacturing demands the highest levels of precision, cleanliness, and reliability. The requirement presented to us was to design and deliver a high-quality heating and recirculation system capable of handling both highly corrosive chemicals and ultra-pure water. In addition, the system needed to feature online digital control with the option for PLC integration—and all within an extremely tight timeframe.

The Solution

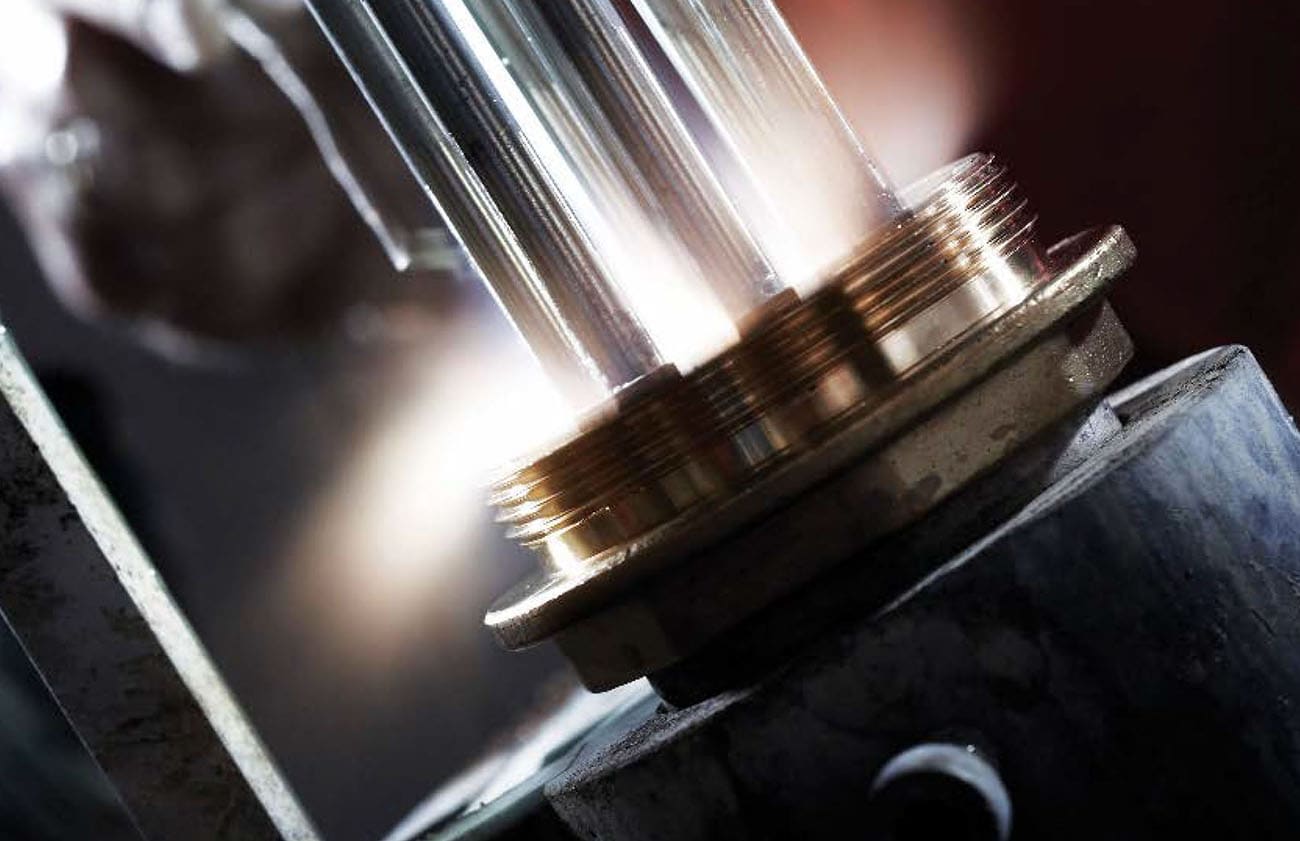

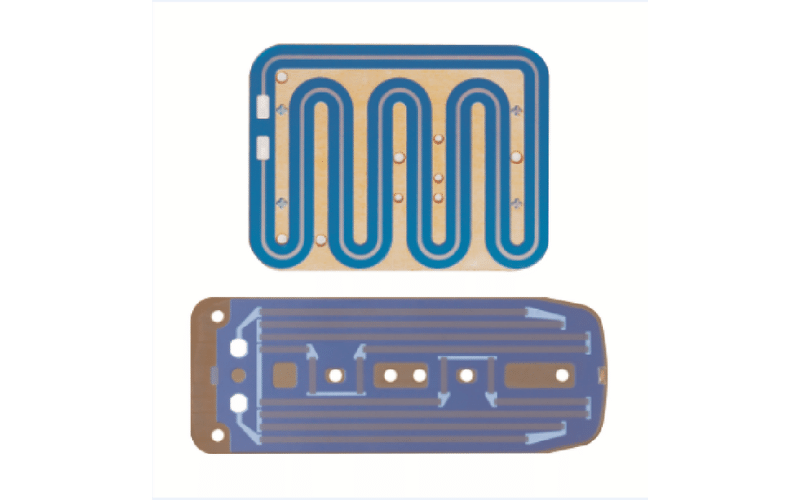

With over two decades of experience supporting cleanroom environments, Braude was well-equipped to respond. We selected our Electrojet Stream inline heat exchangers, available in ratings from 3kW to 24kW, and paired them with our J-Series chemical transfer pumps to create a robust and efficient recirculation system.

To ensure precise control over temperature and fluid levels, we integrated our proprietary HRDc digital controllers and Levelmaster units. The system was engineered as a plug-and-play kit, significantly reducing installation time and simplifying future servicing or component replacement. Crucially, maintenance can be carried out without draining or disturbing the process chemicals—an essential feature in high-purity environments.

Key Advantages of the Braude Heating & Recirculation System

- External Installation: The Electrojet unit is installed adjacent to the process tank, maximising internal space and allowing full utilisation of the tank for processing.

- Protection from Damage: With the heating element located externally, the system is safeguarded against mechanical impact from workloads.

- Simplified Maintenance: The freestanding design allows for easy access and servicing without the need to dispose of costly chemicals—minimising downtime and operational costs.

- Corrosion-Resistant Construction: Manufactured from high-integrity polymers, the system is engineered to withstand even the most aggressive chemical environments.

- Efficient Heat Transfer: Continuous recirculation through the Electrojet ensures optimal heat exchange and uniform temperature distribution.

- High-Capacity Output: A single Electrojet unit delivers sufficient heat for high-volume and continuous production processes.

Braude’s Capabilities for Cleanroom and Semiconductor Applications

Braude offers a comprehensive range of solutions tailored to the stringent demands of semiconductor manufacturing, including:

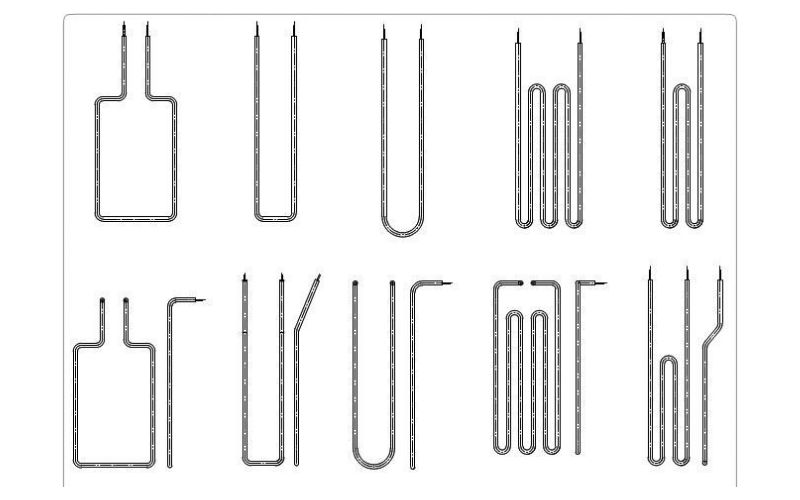

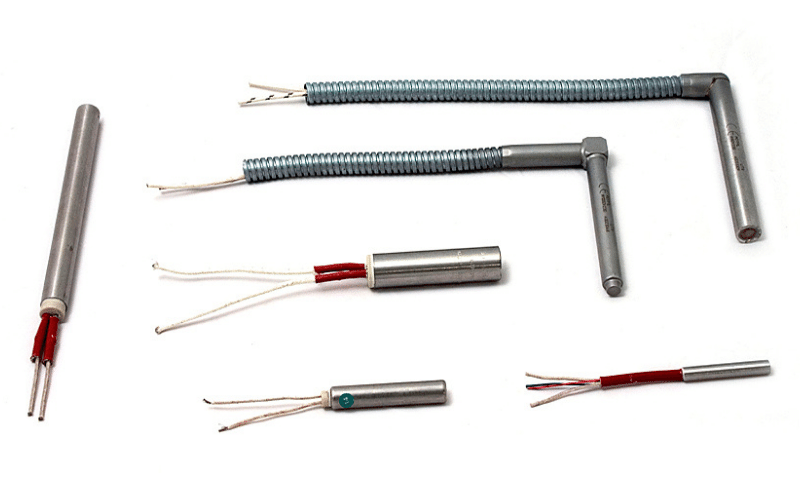

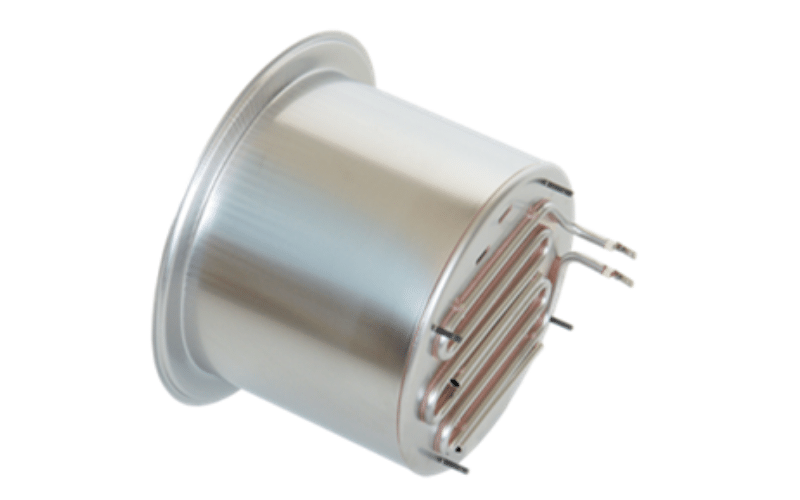

- Polaris Popular & Modular non-corrodible electric immersion heaters

- HRDc, Tankmaster, Thermaster, and Levelmaster process controllers

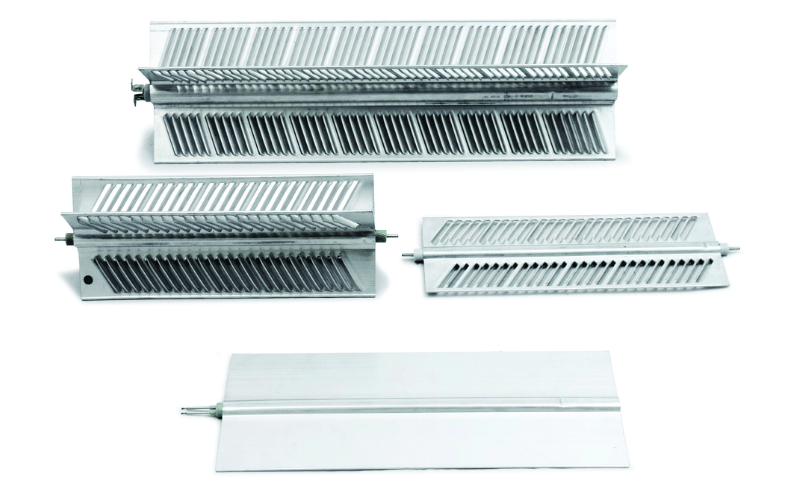

- Electrojet & Electric Jet Stream heat exchangers for large-scale applications

- Chemical transfer pumps

Backer Heatrod offer design, production and supply of electric heating for the process industry, providing products meeting all relevant standards and tests. Certifying products to customer specifications, we design, develop and manufacture all types of systems for electrical heating of gases, liquids, vapours and solids.

%201_element.jpg)

%201-industrial.jpg)

%201-projects.jpg)

%20(2)%201500x500.jpg)