Published date:

Are you optimising your food and beverage production process?

Heatrod Elements are a local UK manufacturer and like most producers in the UK we are always looking at ways to improve our processes, become more environmentally friendly and reduce our energy costs. Heating technology is ubiquitous in the manufacturing environment and this is why we are passionate about improving our client’s processes.

Applications exist throughout all industrial manufacturing sectors and a typical example of where heating technology is key is the food and beverage production sector. Anything from alcohol to oils have their own specific heating requirements and this is where electric heating technology gives maximum flexibility and control.

Let’s take a couple of examples:

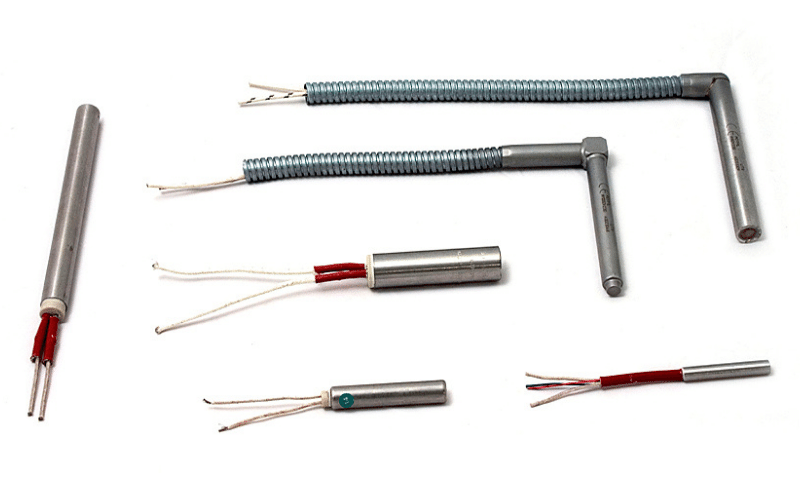

Wine producing in the UK is becoming more and more prevalent and although we are benefiting from marginally increased summer temperatures in the south of the country there is still a need for producers to be able to sustain the correct specific heating environment to produce the best wine. Electric Immersion heaters come in all shapes, sizes and power ratings and when it comes to wine making it’s also the control which is key. To keep a fermentation process within a very tight temperature range is exactly what our digital immersion heaters are designed for. Set your temperature range and fine control of our electric heat source will keep the wine fermentation temperature at just the right levels to maintain a quality product. Heatrod manufacture a variety of heating solutions for food and beverage production processes from wine making to beer brewing. If you’d like one of our applications team to talk to you about your process just contact us through the various channels on our contact us page.

Edible Oils are used through the food and beverage industry as ingredients and cooking media for all sorts of processes. Edible oils are typical to many other types of oils in that their viscosity will increase the colder they become. Viscosity is a measure of a liquid’s ability to flow. Most food manufacturing processes will quickly grind to a halt if the oils they use won’t easily flow through pipes and into/out of tanks. Also, as viscosity levels creep up so does the cost to pump these types of liquids around the factory so this is generally a key issue for food manufacturers in order to maintain both the consistency of their products as well as the sustainability and cost of their processes. Typical applications for electric heating in edible oils are:

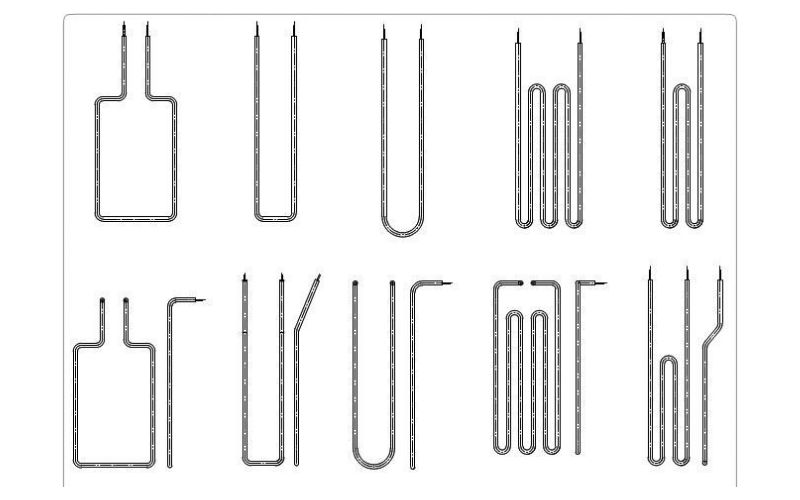

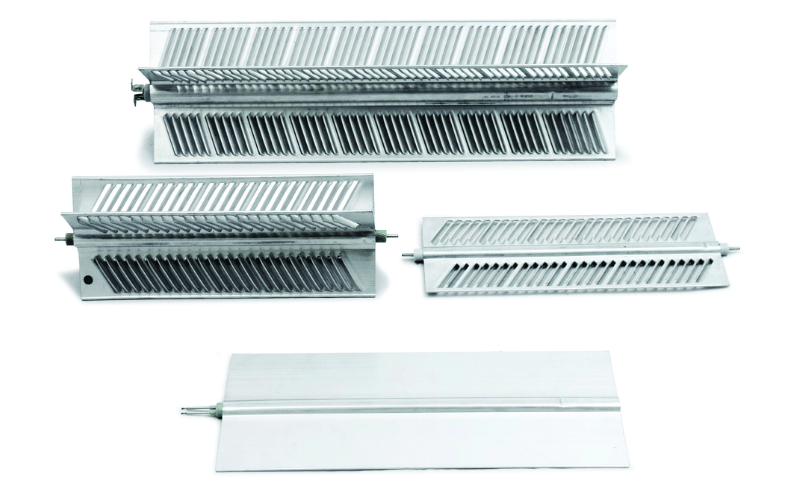

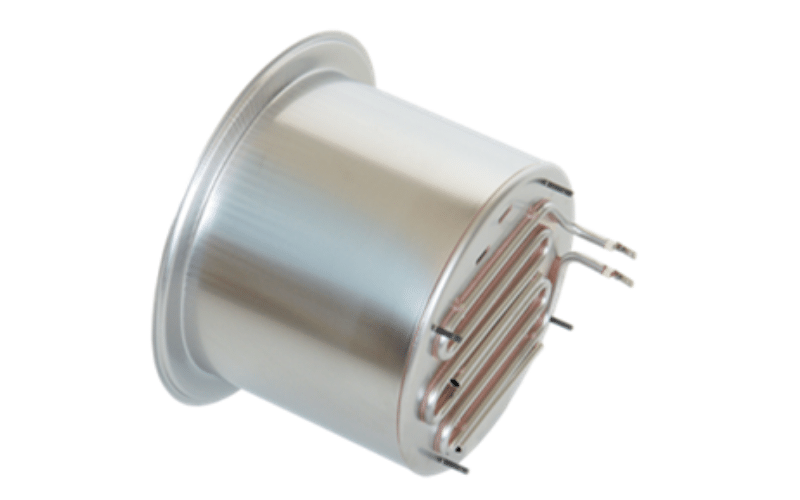

- industrial immersion heaters for tanks

- electric process flow heaters for pipework (in flow)

- heating cable (external to pipes)

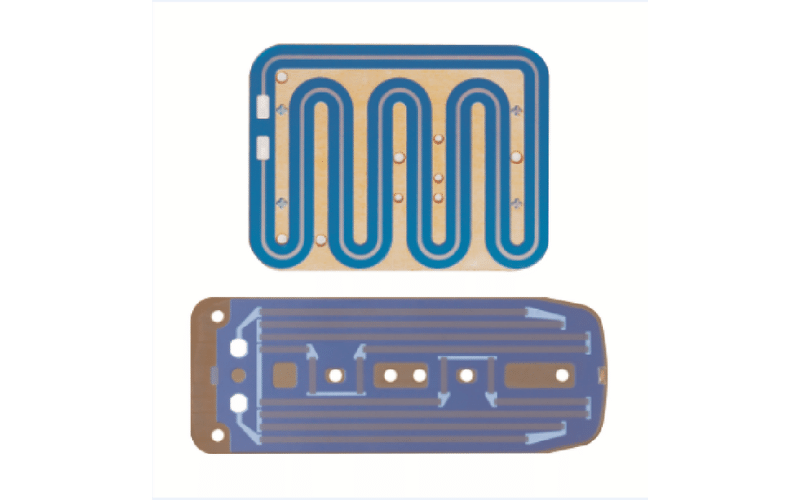

- heating foils & jackets (external to pipes/tanks)

Another key issue in heating edible oils is to get to the required temperature levels without burning the oil. This requires careful understanding & planning of the specific level of heat produced at a given point by the heating device being used. An example of this is the surface temperature of the heating element/s in an industrial immersion heater or process flow heater. If the watts density is too high or the heating element not controlled properly the oil will burn and quickly create contamination around the heater. If the watts density is too low and/or the heating element is not large enough then the heat up times become inefficient.

When it comes to specific industry sectors like the examples we have given in food & beverage, every electric heating application can be different which is why Heatrod Elements have an application engineering team aimed at servicing our customers and potential customers in the UK market. Please don’t hesitate to contact us if you require a more in depth consultation!

%201_element.jpg)

%201-industrial.jpg)

%201-projects.jpg)

%20(2)%201500x500.jpg)