Heat Exchangers

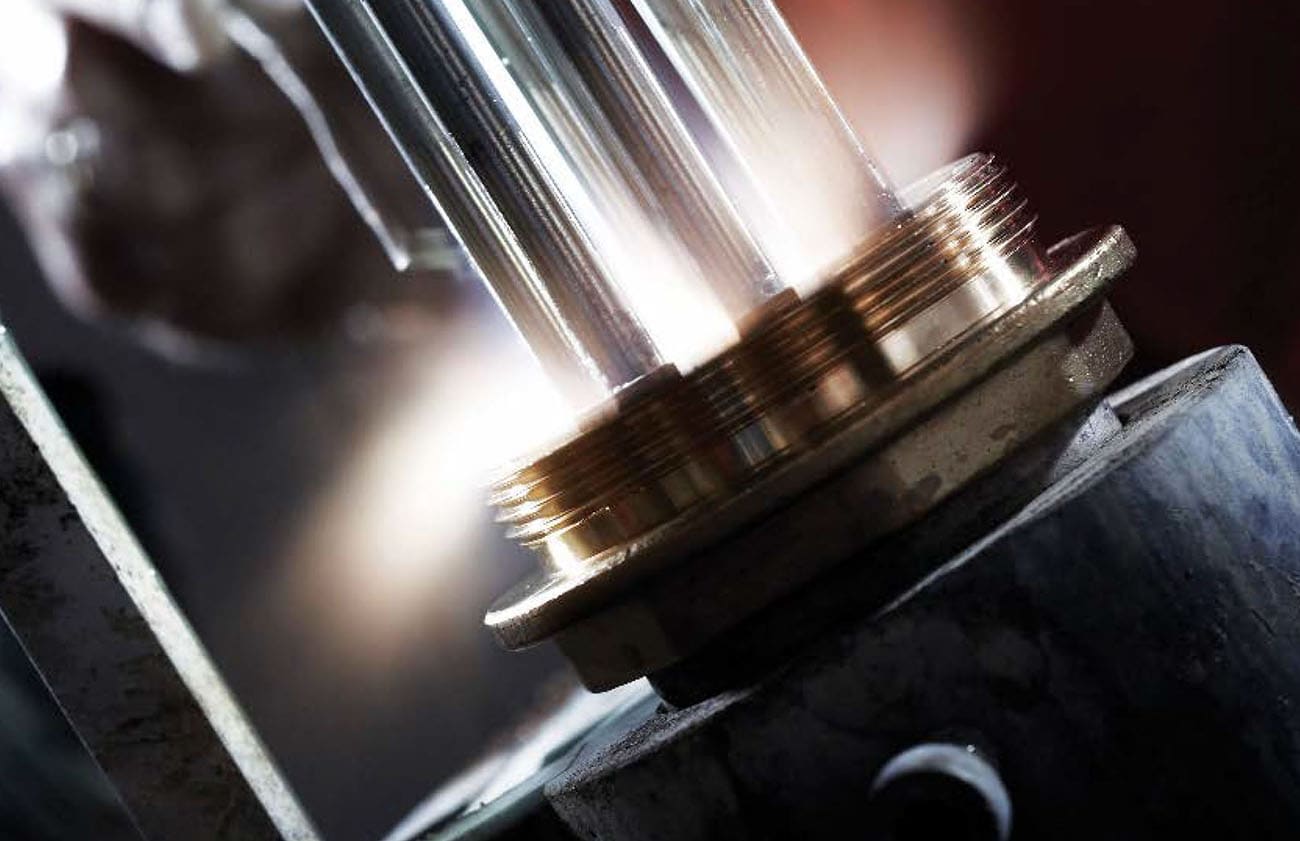

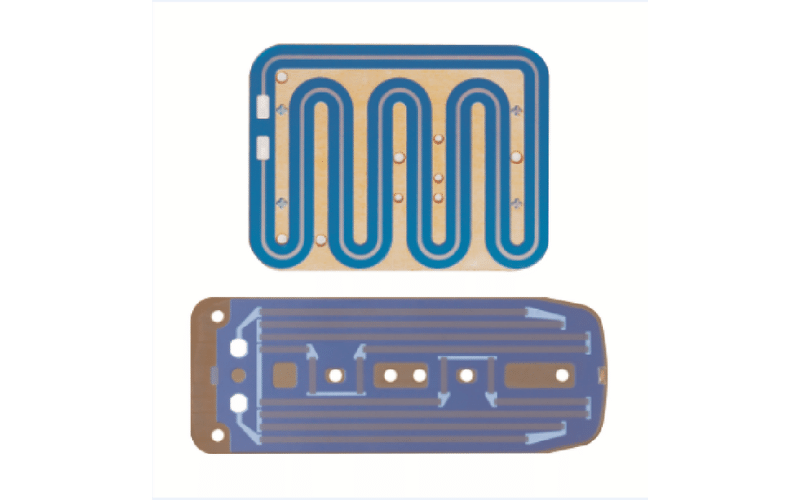

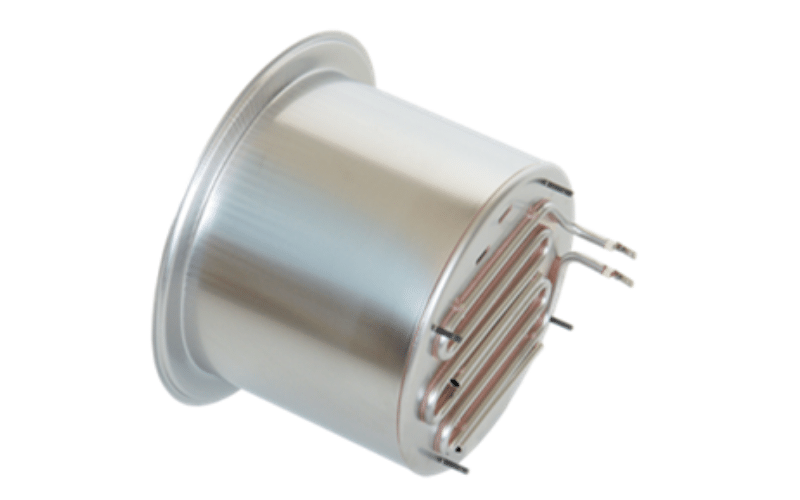

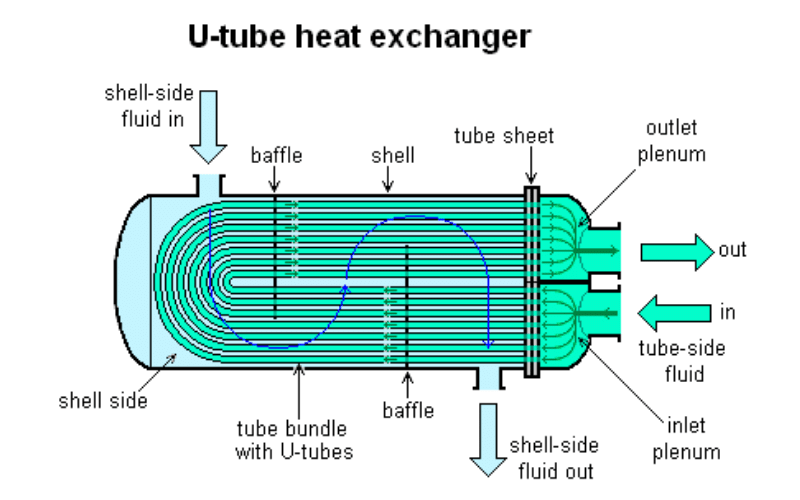

The function of the heat exchanger is to exchange energy between two media. Our tubular heat exchanger can manage a higher pressure (on the secondary side) than a Plate Heat Exchanger (PHE) but the biggest advantage is the possibility to include supplementary heat in the same unit and still keep it’s compact format. This can offer possibilities for room saving application design.

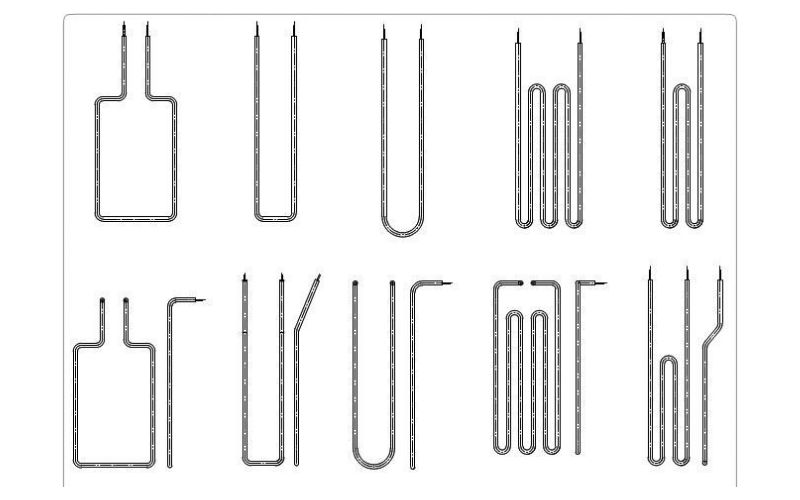

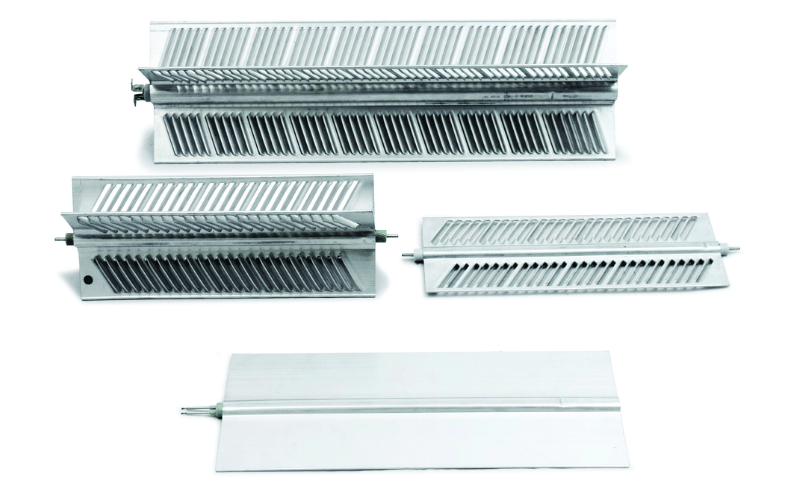

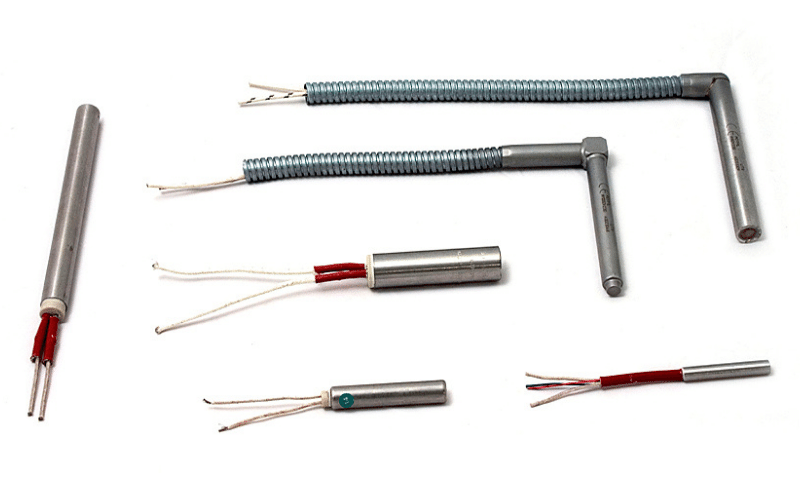

Often our heat exchangers are used in the process industries for electrical process heating. Unlike heat exchangers which use recovered heat from other parts of a manufacturing process, our process heaters employ electrical elements which can produce a significantly more compact solution. Heat exchangers are produced with welded and seamless tubes from our standard range of products according to customer specification.

%20Heat_exchanger_cat%20800x500px1.png)

Example of Applications

- Process heating

- Solar heating

- Food & beverage

- Heat pumps

- Plastics industry

- SPA baths

Benefits

- Optimised plate pattern for maximum heat transfer

- Asymmetric design allows for decreased refrigerant amount in heat pumps

- Compact size combined with high strength

- Easy to install with tailor-made connections

- Couple with thyristor controll for greater efficiency

Flexibility is also maximised as there is no reliance on secondary process heat and so instances such as cold start do not have to be given contingency plans.

Our sister company Loval has manufactured copper brazed stainless steel plate heat exchangers for over 10 years. The HPA-52A is especially designed as a condenser or an evaporator for a heat pump. The asymmetric design increases the overall performance while simultaneously allowing a 30% reduction in refrigerant amount. Tests in Loval’s heat pump laboratory where we simulate a ground source heat pump show that Loval’s HPA-52A is one of the best plate heat exchangers on the market.

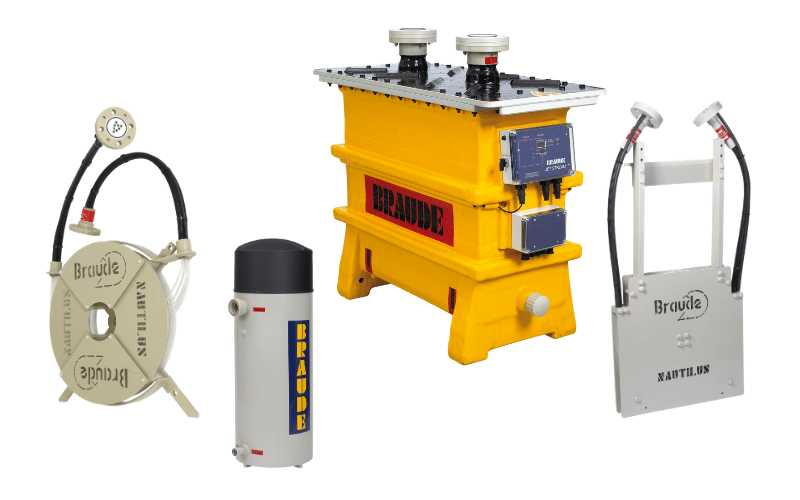

Our Braude brand manufactures a range of heat exchangers in fluoropolymer materials for use either in tank or external. Amongst the many applications in which these heat exchangers are typically used are acid pickling processes, preflux in galvanising, large scale electroplating, chemical milling.

The exchangers are designed for use with steam, hot water, thermal fluid up to 200°C or chilled water for internal or external use and electric for external use. Please contact us for further information.

-

Technical data

Material

Stainless steel acc. to customer specification

Dimension

Same size range as traditional PHE e.g. Ø 130mm, L: 350mm

Assembly

With standard connections

Connections

Cables, screws, tab terminals acc. to customer specification

Design

Tubular design

Others

Designed acc/to plumbing standards

Other cables and fixings available - please enquire.

%201_element.jpg)

%201-industrial.jpg)

%201-projects.jpg)

%20(2)%201500x500.jpg)